Editor’s Note: After the untimely passing of Pat Rogers in 2016, readers asked us to reprint some of his best articles. Though this piece is ten years old and Pat was known for his constantly evolving TTPs, in the area of carbine cleaning, his views remained basically the same. He was also a fan of Slip 2000 weapon lube for the rest of his life.

I grew up at a time when most every male had seen some military service, and I was treated to numerous tales of life in the service of this country in combat and in peacetime. That exposure, and a strong desire to get out of the city and do something that mattered, led me to enlist in the Marine Corps shortly after my 17th birthday.

Table of Contents

The Religion of Cleaning

While I had fired rifles and pistols before, my education was informal and generally limited to what my Dad and others remembered, as well as articles in the various gun-related magazines of the time. Cleaning was something that took on an almost formal overtone and was continued for three consecutive days.

This paled in comparison to what I was taught in the Marine Corps Recruiting Depot (MCRD), where cleaning was in fact a religion, and reached Jesuitical proportions at Parris Island. Brand-new M14s were scrupulously scrubbed on that three-day schedule, a remnant of the use of corrosive primers during World War II. No one had bothered to tell the Marine Corps that that was then, and this was now, so three consecutive days it was. Interspersed with the cleaning lectures were equally ardent lectures about why we shouldn’t believe all the gun magazine and newspaper articles bemoaning the adoption of the M14 and how this monstrosity would lead to the demise of the Western world.

Surprisingly, when we got to the Infantry Training Regiment (ITR) at Camp Geiger, we were issued M1 Rifles, and all the T/E equipment was what we would now consider old school—M1918A2s, M199A4s, etc. The training schedule was all field oriented and we shot what was considered a lot (by 1963 standards). On several occasions after returning late from the cold and wet North Carolina training sites, I marched my squad straight into the shower. We scrubbed the mud off our rifles, 782 Gear, and bodies. We brought the rifles into the squad bay and briefly cleaned and lubed them on the deck while using the miniscule cleaning gear we were issued or purchased. We squared our gear away and grabbed a few hours’ sleep before heading off to learn something new about killing other humans.

What a great life!

Time to Lean Time to Clean

I was initially terrified that we weren’t spending enough time cleaning those old M1s, but they continued to work as long as they were properly lubed and moderately cleaned. Then I began worrying that the M14s might be more fragile if they required such constant attention as taught at MCRD. How could that be? After all, they were similar in many respects, so why did one require much more cleaning than the other?

The short answer is that they don’t require a different cleaning regimen because they are different rifles—it is just that cleaning has to be looked at from several widely divergent points of view.

The first and most obvious is that, if there is sufficient time available for cleaning, that time will be used for cleaning, meaningless or not. Second is that, under exigent circumstances, a quick cleaning, paying particular attention to salient points, may be all that is necessary to keep the weapon running.

A military issue is that in many units the armorers—and sometimes even an officer—will conduct what amounts to a “white glove” inspection, wherein the troops will be kept “busy” by performing useless, and sometimes harmful, “cleaning” in order to satisfy the whims of despots and buffoons. Removing protective lubrication or scraping away finish does nothing to improve serviceability. It only destroys the guns and angers the troops.

When the M16 first came upon the scene (shortly after the M14), it was a shock to those who believed in wooden stocks, match sights, and big bullets. It was billed as needing minimal cleaning, which turned into self-cleaning, which turned into no cleaning as some rifles were issued in country without cleaning equipment. Several issues combined to make a tolerance stack, and malfunctioning rifles were the result.

Probably as the result of these issues in the late 1960s, a myth of grand proportions has swelled up concerning the care and cleaning of the AR platform. This myth specifies that the AR must be kept spotlessly clean, and that it takes an hour (if not more) of steady cleaning for the rifle to be once more useful. Indeed, because this rifle allegedly dirties where it feeds, it must be cleaned regularly and with great care if you are to use it. Also, a few meager grains of sand will cause it to stop running.

Remember Jessica Lynch

The highlight for many errornet pundits comes when they rally around a female soldier whose convoy was ambushed during Operation Iraqi Freedom. “Remember Jessica Lynch” has become a cry of the unknowing, and while the subject makes for great points for their side, it is flawed.

Reports concerning this incident state that weapons malfunctioned to be sure. But a sergeant in that convoy stated the weapons were cleaned daily and were clean when they left that morning. The M16A2 wielded very efficiently by a soldier who killed six of the enemy with it did malfunction—because of a faulty magazine and broken extractor. This is a service-life issue with the rifle, not a design flaw. While leadership and depot-level maintenance might have prevented something like this, the proper steps were not taken at a level above the soldier in the field. An M249 also failed, but that may have been due to lack of training with the weapon. And what of the celebrated centerpiece of this fight? She may have been knocked unconscious when her vehicle crashed at the beginning of the action—but this is casually brushed aside in the bubble gum (gun) forums. The serviceability of her weapon is therefore moot.

Here’s a news flash: Sand in the chamber will stop most guns—M16s, AK-47s, M24s, M1s, M9s, and so forth. It is not unique to the AR platform.

Cleaning is a hot-button topic, and a great many (especially AR detractors) really believe that the AR has to be kept meticulously clean to function. While having a clean gun is never bad, neither do you have to put up with the white-glove nonsense.

Cleaning Regime That What Works for Me

My cleaning regime may be different from conventional protocol, but it works and has stood the test of time. I normally spend no more than ten minutes doing a field cleaning, and oftentimes less than that. If it takes you an hour, you are wasting time on something or you are doing something wrong.

This is the cleaning protocol I use. This isn’t “the” way, but rather “a” way. I don’t pretend to know everything, and I wind up learning something new almost every day. Not using what is listed below won’t necessarily get you killed, make you unattractive to a potential mate, or make you unpopular at the local gin mill.

- Field strip the carbine and punch the tube with a wet patch. Leave the chemicals to do their work and get to the bolt and bolt carrier assemblies.

- Spray the bolt with Slip 725 Gun Cleaner or Evinrude Johnson Engine Tuner and let it sit.

- Clean the bolt carrier assembly by removing carbon from the bolt cam pin slot, inside of the bolt carrier (yeah, that chrome-lined thing where the bolt goes in) and the bottom of the bolt carrier itself. You can use a wet pipe cleaner to clean the inside of the bolt carrier key, but I rarely do. Do not put anything inside the gas tube—it is unnecessary, and you will only stick debris in there that can do no good.

- Use your toothbrush and a rag to clean the bolt, specifically the bolt lugs. Do not concern yourself with the carbon build-up on the bolt’s tail. No matter how you clean it, it will just reappear the next time you shoot it. I had an armorer once tell me that the carbon promoted corrosion. That may well be if the gun is never shot, but I have yet to see a working bolt corrode away.

- Attach the chamber brush to your cleaning rod and scrub out the chamber. I generally use a worn brush, wrap a wet patch around it, and insert it in the chamber. Spin it a few times and replace it with a fresh brush and patch. Spin that and then dry the chamber out. Clean out the locking lugs with cotton swabs.

- Spray some Slip 725 into the upper receiver and the charging handle. Your toothbrush and cotton swabs work well here.

- Take a few dry patches and clean the barrel. Note that I don’t normally use a bore brush, and allow the cleaning fluid to take care of the bore.

Before the rockets start flying, let me state that I used to shoot Service Rifle and am a High Master and a Distinguished Rifleman. I rarely used a brush on my M14NM or match AR-15s. If I felt the bore was heavily fouled, I ran several wet patches through it, and if I absolutely felt the need for a brush, it was nylon, not copper. Never use a stainless steel brush in your barrel.

Understand that this is for a carbine, which by virtue of its definition is a short-barreled rifle. The 5.56x45mm service rounds and M4 carbines are capable of hitting out past 500 meters, but shine in fights that take place under 200 meters. Bothering with inconsequential increments may not be useful under these circumstances. If you have an DMR type, by all means give that barrel the care it deserves, but that care may be wasted on a 10.5- to 14.5-inch carbine.

Reassembly

Before reassembling, check your bolt rings for serviceability. Insert the bolt into the bolt carrier and turn it upside down (preferably over something soft). If the bolt falls out on its own, you need to change the gas rings. If not, you are good to go.

Don’t get locked into the nonsense of misaligning the gas rings. Colt Armorer instructors state emphatically that the gun will run with only one good ring, and I have done exactly that. For about ten years, we have been teaching that misaligning the gas rings is a waste of time. I have seen nothing that leads me to believe differently.

One of the very prominent AR myths is that the gun runs better dry. In fact the AR series runs significantly better wet than dry, but some approach this with such trepidation that they steadfastly refuse to use only a tiny bit of lube on their carbines, causing them to cease functioning after a very short while.

Hundreds of e-net posts speak of using little lube on the carbines, believing that too much lube is the cause of all problems. A friend, a retired Marine MSgt and prolific Class 3 collector, looks at lube like it’s two-day-old cat urine and is absolutely phobic about putting anything more than a drop or two on any gun.

Our experience is that, after poor magazines and operator-induced malfunctions, dry guns are a major cause of stoppages. We see this in every class we have ever attended or taught, and are satisfied that our observations regarding lubrication are correct.

Consider that your carbine is a machine and, like an internal combustion engine, it requires lubrication to make it function. Certain wear points in the gun need attention, and failure to do so can cause a stoppage. A good rule of thumb is to look for shiny marks, which indicate metal-to-metal contact. If it shines, get it wet.

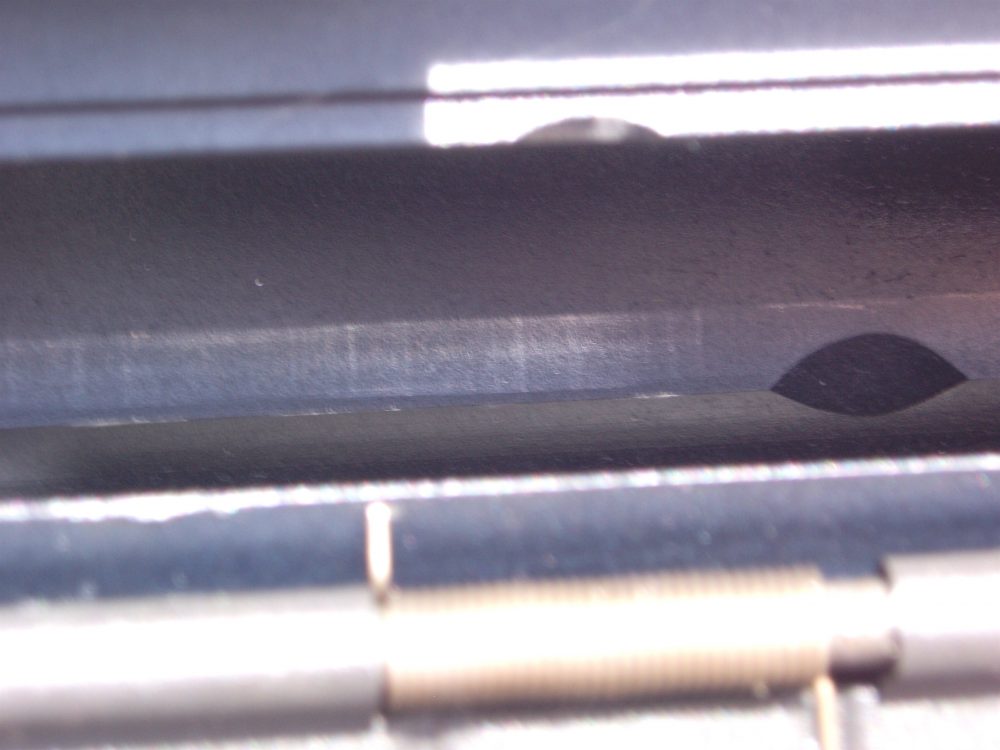

Remove the bolt from the bolt carrier. Turn the bolt carrier over and observe the shiny area on the bottom. This is a wear point. The slot the bolt cam pin rides in is another wear point, as is the chromed hole in the bolt carrier that the bolt rides in. The entire bolt carrier can use a coat of lube, but pay particular attention to those areas. The military also states that a drop down the bolt carrier gas key is required.

The bolt itself requires a coating of oil, paying particular attention to the bolt rings and lugs. Those bolt rings function just like the piston rings in your car engine. How long do you think your ride would last without lube?

A properly cleaned and lubed carbine should go a minimum of 500 to 1000 rounds without any cleaning at all. Using a suppressor will cut that number down drastically, as will firing multiple rapid-fire strings or firing with the selector switch on “Group Therapy.”

I advise shooters that during the chow break they should place a few drops of oil into those two gas ports on the right side of the bolt carrier. The lube will get into the gas rings located handily nearby and keep your gun running smoothly.

Finally, a few drops of oil into the underside of the charging handle are not a bad thing.

The AR system runs much better wet than dry, and we see that during every class. Understand it is not only the amount of lube used, but also the placement of the lube. At one class, a very experienced shooter was having functioning problems. He pulled back on the charging handle to show me the bolt was wet, but when he released the charging handle, I could see that the area on the bolt carrier adjacent to the gas holes was dry. I placed two drops of Slip 2000 into those holes and the gun ran fine.

In Summary

The moral of this story is not just to put lube on, but put it on in the right places.

When at class and shooting 400 to 1000 rounds per day, the bolt will get blown dry. Adding oil during break time will keep the gun running and keep you learning new skill sets instead of becoming frustrated with a constantly malfunctioning gun.

In the 1990s, I worked for a government agency that had a large budget. We had a fair number of guns and a lot of ammunition, so on down days I had the opportunity to run some informal tests. While the exact results have been lost to the ages, some salient points remain embedded in my brain-housing group.

A totally dry gun will run approximately 100 to 200 rounds before seeing problems. A clean, properly lubed gun in good condition should go from 500 minimum to 1,000 maximum. More lube is not necessarily bad. I submerged bolt and bolt carrier assembly in a bucket of oil, shook it off and placed it in the carbine. It ran like a clock, though I only had enough time to fire off four mags’ worth of M855 through it.

I have used every type of lube imaginable, from WD-40 (especially good when you have a dirty gun), to 3-in-1 oil, suntan lotion, butter, and even Vagisil—don’t laugh, it works. I may not want to use any of them for the long haul, but for a quick fix, they beat having a non-functioning gun.

The type of lube you use is another topic that is full of mythology sprinkled with fact. While the military uses CLP, a book several years ago cautioned against using it for cleaning as it ”promotes carbon.” Why it only promotes carbon for cleaning and not lubricating is a mystery to me, but I don’t use CLP for anything anymore.

Commercial choices abound, from mystical concoctions of “Sergeant Major’s brew” to a host of “this is the best stuff ever made and we’ll sue anyone who says different” crap. I prefer to stay away from most petroleum-based products, and use Slip 2000 for lube and that same company’s 725 Cleaner and Degreaser for the other chores. Slip 2000 is aqueous based, eliminating a lot of the contamination issues seen with petroleum products, and their products flat work. I have found Slip 2000 to be excellent and the company’s owner, Greg Connor, is a great American.

If I need grease, it will be TW25B (known in the Marine Corps, where it is used on up-gunned weapons stations on AAVs as “elephant sperm”). If you prefer to use eye of newt and toe of frog—have at it. My name isn’t attached to any of it, and if you found the absolute key to the cleaning universe, go for it.

My experience over the years as a Marine and a cop and working with sister services, foreign governments, police departments, and civilians from all walks of life leads me to some inescapable conclusions.

First is that firearms are machines, and unless you keep them in the safe, heavily lubed, they will exhibit wear. Shocking but true: nothing lasts forever, and the harder you shoot them, the shorter their lifespan. Proper maintenance and cleaning will extend their useful life, but they are going to give up the ghost one day.

Second is the fact that all guns are no more equal than all people are. The malfunctions I see at military classes are the result of worn-out guns and bad magazines. In the open enrollment classes, the malfunctions I see are poor quality control on the aftermarket guns, bolt carrier gas keys not staked or staked with a limp wrist, bad magazines, and improper lube.

I try not to be shocked and amazed at the poor quality guns being turned out by many, but then the homemade guns—the so-called Frankenguns built with gun-show parts and little knowledge—lead me to believe that in the gun world, P.T. Barnum would be a master.

That isn’t to say all the companies aren’t capable of turning out good (even great) guns, and often they do. But as a good friend often states, “Even a broken clock is right twice a day.” I’m not impressed with the bleats of, “Well, I’ve had this gun for ten years and it has never ‘jammed’ once.” Of course not. Malfunctions only occur when you fire them. I have seen enough of most types to realize that the only ARs in my company’s armory are those that meet a standard.

In Closing…

Any gun is a machine, and once in your paws, it must be properly maintained. That does not mean incessantly cleaned with obsessive fervor, but rather taking care of those areas that affect functioning. Keep a gun book and annotate it with round counts so you can figure out when certain parts (extractor springs, gas rings, bolts, and barrels) need replacing. Replace these parts before they replace you.

Keep the gun lubed to reduce friction, and understand that the more you use it, the more parts need to be replaced. Accept that as a fact of life and drive on.

Click this link for more articles by Pat Rogers

SOURCE

SLIP 2000

(888) 243-6725

www.slip2000.com

1 comment