When the historians look back on the first decade of this century, they are likely to call out the widespread acceptance of two things that greatly advanced the capabilities of the rifleman: the 1913 rail and the MOLLE interface.

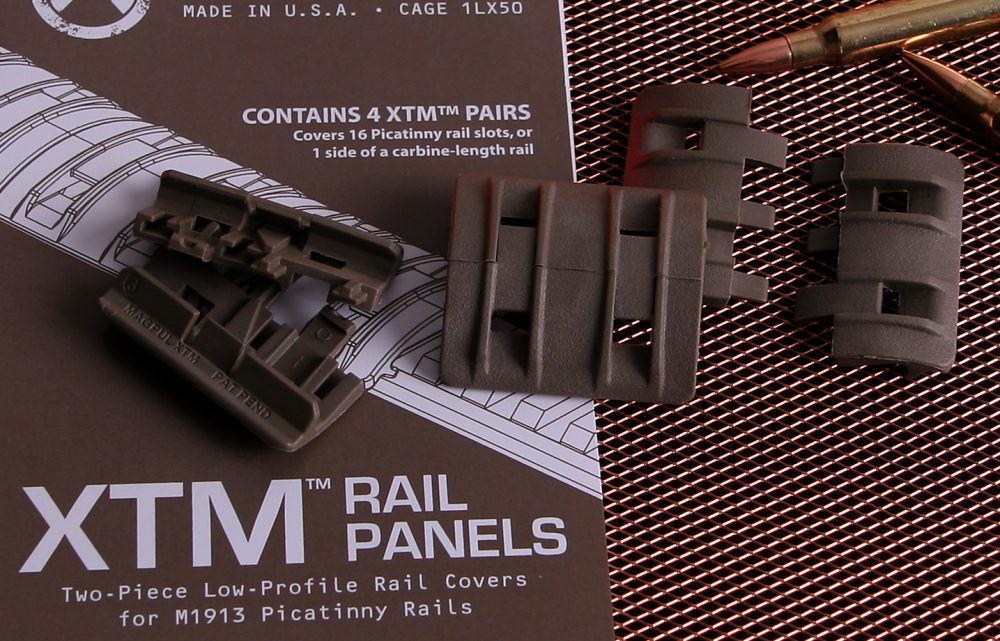

The now ubiquitous Picatinny rail has made it incredibly simple to attach, swap or individually configure for mission profile optics, lights, lasers, grips, swivels—you name it. Options for covering the rails have been provided by a number of vendors in similar fashion, but Magpul has provided another take on a solution with the introduction of their XTM rail covers.

Magpul XTM is an innovative connecting rail cover that fastens onto Picatinny rails.

The XTM is a two-piece design that matches up and clicks together somewhat like a familiar Fastex buckle to cover four rail positions. The cover is locked firmly in place with zero movement fore and aft or side to side and can be removed by prying up the locking tabs with the tip of a round object. I was able to use standard issue green tip, a small Phillips head screwdriver, an ink pen and similar common objects to disconnect them with no fuss. Magpul recommends that knives or other sharp objects not be used to prevent damaging the cover or slipping and cutting yourself, since you are prying in opposing directions at the same time.

This ability to remove the cover from in between rail-mounted objects is one of its most obvious design advantages. I am familiar with many leaders who have taken their troops to get solid zeros on their optics and lasers only to find that a well-meaning armorer or NCO required the weapons to be thoroughly free of dust/sand. So the riflemen dismounted the optics in order to slide off the rail covers and clean underneath, thus negating the whole point of the exercise.

XTMs (center) shown for size comparison against Knight’s and ladder-type covers.

If the DOD would spring for quality return-to-zero mounts like LaRue Tactical’s, it would prevent such common shenanigans, but that is hard to explain to the accounting department. The XTM panel in such a scenario allows the cover to be popped loose without affecting the surrounding gadgetry.

Rail covers can serve a number of functions. They allow the shooter to customize the feel of the forend to a degree never before possible. Covers also protect the support hand from heat in high volume of fire situations. Covers protect the integrity of the 1913 rail itself, preventing dings and damage that might prevent something from later being mounted at the unprotected location.

Less importantly, the cover can be used for miscellaneous purposes such as a mounting point for camouflage or tape switches, or providing texture or resistance to be used by the support hand, or to help provide stability in barricade shooting.

Loose rounds can be used to separate halves of XTM cover, allowing user to remove them from in between mounted rail accessories.

The XTM is the thinnest of the full rail covers, being just slightly smaller than a military-issue Knight’s rail cover. This can be good or bad, depending on the shooter’s preference. I really like the feel of the XTM covers and was surprised at how small the forend felt with them installed. They have a slight convex curvature that, although low profile, provides a somewhat round feel to the handguards.

The covers still provide enough protection to get the hand away from any heat, more so than ladder-type covers, but I can’t say that they are any better or worse than other full covers. There is enough material between the rail and the outside world that there should be ample protection for the rail itself.

The design of the XTM incorporates four small holes. These might be used as a mounting point for camouflage in some applications, or a small zip tie can be run through to secure a tape switch. I was able to use light wire to affix a white light securely to the rail cover—a nice capability to have should a primary light become inoperable on an extended mission.

The mounting options are subtle but very useful features that provide the user with options that previously didn’t exist. The interchangeable nature of the two halves of the cover allows them to mate with other colors to provide some breakup to the pattern for those who are not allowed or do not like to paint their gear.

XTMs incorporate holes that can be used with 550 cord, cable ties or light wire to mount tape switches, camouflage material or allow field-expedient mounting of a white light.

I can remember the initial issue of the M4A1 with rails. Supply of the issue covers was often short, so it was not uncommon to run one “nekkid.” One byproduct of this was that the shooter could use the rails to nearly Velcro himself to barricades for support in making a tough shot. However, the carbine would saw through gear and skin when carried on long movements, and heat against bare hands was a real issue.

The XTMs have four small ridges molded in per section, slightly less tall than those on a Knight’s rail but less rounded. I found that this slightly square profile allowed the rifle to “stick” very well when braced against a post or corner. However, the ridges were in no way uncomfortable or abrasive against clothing, gear, or skin.

A fair question when looking at the XTM’s thinness and locking system is, “How long will it last?” I embarked on an unscientific test, mounting and unmounting one section 75 times. The locking tabs showed some disfigurement but still held firmly.

I then joined the halves and suspended a stack of bricks from strings run through the holes in the opposite halves of the pair. It held the weight with no problem, which suggests that the system should stand up to long-term use on a weapon.

Thinking back, I don’t recall ever unmounting covers from my rifles more than a half-dozen times in the course of adjusting gear location or cleaning over a deployment, so the XTMs will probably outlast the bolt and barrel of the weapon they are attached to.

The current variety of Picatinny rail accessories is a real boon to the end user. The Magpul XTMs are a welcome addition to these and should provide users with capabilities not found in other products.

SOURCE:

Magpul Industries Corp.

Dept. S.W.A.T.

400 Young Court

Erie, CO 80516-8440

(877) 462-4785

www.magpul.com