I first saw the Para USA Tactical Target Rifle (TTR) at the NRA Convention in Phoenix, Arizona in May 2009. While intrigued with the rifle’s features, I did not have a chance to obtain one for evaluation until early 2010.

With the prevalence of AR manufacturers, one may ask if we need yet another variation from yet another manufacturer. If you believe that everyone should own the exact same brand, model and color of automobile, the answer is “no.” If, however, you believe that it is your right to own as many—and as many variants—of any firearm you wish, the answer is a resounding “YES!”

There are two versions of the TTR. The TTR-XAS has a partial rail forearm (only the front 3 ½ inches of the forearm has rails at the 3, 6 and 9 o’clock positions), while the TTR-XA has a full rail. The full-rail model (TTR-XA) was the version selected for evaluation.

At first glance, the TTR may appear to be just another AR. Look again.

With stock folded, TTR is seven inches shorter than carbine with collapsible stock and almost ten inches shorter than a fixed stock.

Table of Contents

THE TTR

The operating system of the TTR is what Para refers to as a Delayed Impingement Gas System™ (DIGS™).

In the direct impingement system invented by Eugene Stoner, gas is bled off into a hole under the front sight (or gas block) and travels down the gas tube. The gas contacts the carrier key on top of the bolt carrier group (BCG), forcing the BCG into the receiver extension under spring tension. The recoil spring in the receiver extension then forces the bolt forward into its locked position.

With the DIGS operating system, gas is bled off in the same manner but passes down a very short gas tube and into an operating rod that is permanently attached to the BCG, forcing the BCG to the rear of the upper receiver. The gases are expelled through the Manifold Injector System™ in the bolt carrier, making this a very clean running system. Instead of the recoil spring being in the receiver extension, a very strong recoil spring surrounds the operating rod and forces the bolt back into its closed and locked position.

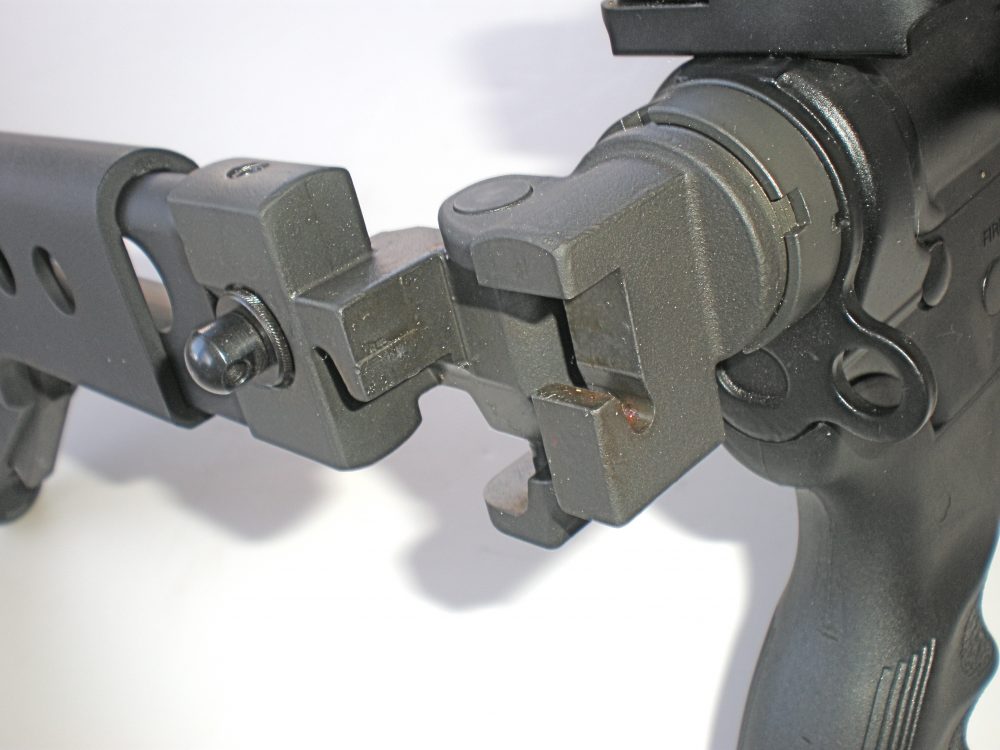

Para calls the stock on the TTR a Rapid Deployment Stock (RDS). The RDS is not only collapsible with five different positions of length of pull, it also folds to the left side. The stock attaches directly behind the stock lock (castle) nut. There is no receiver extension—commonly called a buffer tube—or buffer.

Latch that locks the stock is robust, resulting in very secure lock-up.

Folding the RDS is easily accomplished by pushing down on the top of the hinge with the thumb while the fingers pull up and inward on the stock. Just before fully folding, a cam in the stock rotates downward slightly. While possible, it is not likely the RDS will open inadvertently due to the strong hinge spring. When folded, the length of the rifle is roughly seven inches shorter than a carbine with a collapsible stock, and almost ten inches shorter than a fixed stock.

Opening the RDS is as simple as grasping the stock and swinging it open. As the stock reaches its fully open position, it cams downward about ¼ inch and forces a large male locking lug into its robust receptacle. Lockup is very secure and there is no more “wiggle” than a standard AR stock. The receiver plate in front of the stock nut has loops on either side for attaching a sling.

The 16.5-inch barrel is chrome lined and has a 5.56mm NATO Chamber.

The TTR is supplied with an Ergo Grip (marked Para USA), Yankee Hill Machine front and rear folding back-up iron sights (BUIS), and a Phantom flash hider. Weight empty is approximately 7.8 pounds. The rifle comes shipped in a lockable plastic case with a gun lock, manual and a single black Teflon-coated stainless steel magazine.

While the takedown is different than a standard AR, it is not complicated.

First, a detent at the muzzle end of the top rail—just forward of the front BUIS—is depressed, allowing the top handguard/rail to slide forward. Using the rail, depress the recoil spring and remove the recoil spring clip. Push out the front and rear takedown pins on the lower receiver and separate the upper from the lower. Pull back on the charging handle and remove the BCG with the attached op rod. While it is possible to remove the recoil spring, it is neither necessary nor recommended to remove it due to the pressure it is under.

TTR’s bolt with permanently attached op rod.

ACCESSORIES ADDED

With the folding stock, I think the compact TTR may be very useful for those who operate in and out of vehicles. With that in mind, I chose to equip the TTR with compact sights and light.

Before heading to the range, and to get the most out of field testing the TTR, I installed the new Extreme EXPS holographic weapon sight from EOTech. This new sight only takes up approximately 2.5 inches of rail space due to its transversely mounted CR123 battery. Another new feature of this sight is that the familiar buttons have been moved from the rear of the sight to the left side, making them much more accessible if the sight is mounted close to the BUIS, a magnifier, etc.

Also new with the Extreme EXPS is the adjustable quick-release system, which allows a shooter to remove the sight and remount it with no loss of zero (assuming, of course, it is put back in exactly the same place on the rail). With 20 brightness settings, the Extreme EXPS has a run time of approximately 600 hours at setting 12. Weight is 11.2 ounces.

You can’t shoot what you can’t identify, and therefore I am a firm believer that any firearm used for self-defense should be equipped with a quality weapon-mounted light. For the TTR, I chose the new M300A Mini Scout Light from SureFire. With a length of only four inches, weighing a mere 4.5 ounces, and taking a single CR123 battery, this is a lot of light in a small package.

The Mini Scout Light has a built-in mount to attach to any milspec Picatinny rail with a thumbscrew clamp. Its LED emitter is shockproof and puts out a very useful 110 lumens for almost an hour and a half.

The included pressure-activated tape switch with five-inch-long cord can also be used to activate momentary on.

Gas tube at right of kink on captured recoil spring.

The last accessory added was LaserLyte’s K-15 Kryptonyte Green Laser. Especially for a long gun, a green laser is preferable to a red laser, as the dot can be seen in daylight at much greater distances than a red laser.

Made of 6061 aluminum, the K-15 takes up only three inches of rail space, weighs 5.4 ounces, and uses a single CR123 battery. All controls—on/off/momentary, windage and elevation adjustments, and direction of battery placement—are clearly marked with laser engravings.

Windage and elevation adjustments are made with hex-drive screws and sealed with turret caps. Due to the offset design of the laser tube and battery compartment (side by side), the laser can be mounted on the top rail, putting it very close to the boreline. A 10-inch cord with pressure pad is included. Run time is approximately 1.5 hours.

In addition to their compact size, all three of the optic/light devices above were chosen in part because they use the same single CR123 battery, eliminating the need to carry more than one type of power source.

With the accessories mounted, the TTR tipped the scales at approximately 9.1 pounds. All items were mounted as far back as possible, to minimize the carbine becoming muzzle heavy due to the added weight.

FIELD EVALUATION

If there is a weak link in the AR family of rifles, or almost any semiautomatic firearm, for that matter, it is the magazines used. A wide variety of magazines were used in evaluating the Para TTR.

Thirty-round magazines used in the Para TTR included the three blackened, stainless steel mags that came with the rifle, older GI mags (rejuvenated with new springs from Brownells and Magpul Enhanced Followers and Ranger Plates), Magpul PMAGs, Lancer Systems L-5, Fusil steel magazines, TangoDown ARC , and Bravo Company Mfg. AR-15 magazines with black Teflon finish with Magpul Enhanced and TAPCO magazines.

Due to their compact sizes, all accessories took up only 11 inches of rail. This left a lot of exposed rail. Inclusion of rail covers with the rifle would be a useful addition.

In keeping with the compact theme, I utilized 20-round magazines from PMAG and Lancer Systems, as well as some legacy GI mags.

Since I store much of my 5.56/.223 ammo on stripper clips, for ease of loading and keeping the mags topped off, I used a C-Mag Speed Loader from The Beta Company.

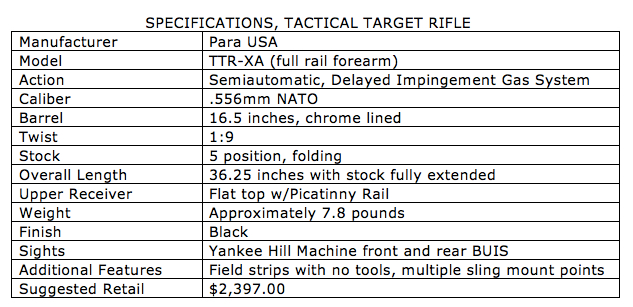

To evaluate the TTR for accuracy as well as function, I used the following .223 Remington loads from Black Hills Ammunition: 50-gr. V-MAX, 55-gr. FMJ, 68-gr. Match, and 77-gr. Match. From Hornady, I used a 55-gr. V-MAX, 60-gr. TAP® FPD™, and 75-gr. BTHP. I also used two 5.56mm loads: Black Hills 77-gr. Mk 262 and Hornady 75-gr. TAP BTHP.

To conserve the “good stuff,” for tactical drills and more extensive function firing, I used reloads loaded with my own 60-gr. bullets made from recycled .22 Long Rifle cases (FREE BULLETS: From .22 to .223, September 2008 S.W.A.T.).

To begin with, I obtained a 50-yard zero with the EOTech Extreme EXPS, with the brightness turned down to give the illusion of a smaller dot/aiming point. I fired ten-round groups from prone to establish an accuracy baseline for each of the loads above using TangoDown’s ACB-4 bipod. The velocity of the loads was established with a PACT Professional chronograph.

The best groups were turned in with the Hornady 75-gr. Match (1.119”) and the Black Hills 77-gr. match (1.22”) loads. This was followed closely by the Black Hills 55-gr. FMJ (1.26”) and the Hornady 55-gr. V-MAX (1.28”). With both the heavier and light bullets, the difference could not be seen by the eye.

Middle ground was taken by Black Hills 68-gr. Match and measured 1.53 inches.

The rifle did not like either of the 5.56mm loads, with both measuring close to around two inches, or the light 50-gr. Black Hills V-Max, which came in at 2.45 inches.

During the initial accuracy/velocity testing, I observed that the TTR had a very nice trigger that had no creep and broke cleanly at 4.3 pounds. This very nice trigger also ended up being one of the things that I did not care for on the TTR. I’ll explain.

Twenty-round magazines in test included (left to right) GI, PMAG and Lancer L5. All mags were loaded/topped off during evaluation with C-Mag Speed Loader from The Beta Company.

Between 200 and 300 rounds, the trigger went “dead” and would not spring back to reset. Separating the upper from the lower revealed the problem.

The TTR uses a JP adjustable trigger, and the adjustment screw had not been secured with Loctite®. When the gun vibrated during the firing cycle, the screw backed out, resulting in the dead trigger. The screw was retightened and testing resumed.

Personally, I’m not a big fan of adjustable triggers on a carbine used for defensive/offensive purposes. When running a gun hard, I have had them fail in my carbines and seen them fail in others often enough not to trust my life to them.

For competition? No problem. Target shooting? No problem. But if the carbine is used in a role where lives are at stake, I prefer a standard milspec trigger and can live with a less than “match” trigger pull. If you do decide to use an adjustable trigger, make double-damned sure the adjustment screws have Loctite on them.

For the remainder of the evaluation, rather than just turning a lot of good ammunition into empty brass, I tuned up my skill sets. On three separate days, I fired over 900 rounds total while evaluating the Para TTR.

Thirty-round magazines used in Para TTR included (top row) black stainless steel mags that came with the rifle, rejuvenated GI mags, Magpul PMAGs, Lancer Systems L5, (bottom row) Fusil steel magazines, TangoDown ARC mags, Bravo Company Mfg. and TAPCO magazines.

To evaluate the DIGS in a worst-case situation, I ran the TTR as it came from the factory (basically dry). Although still functional, it started to become a bit sluggish around 400 rounds. The bolt and carrier were lubricated, and testing resumed.

I did not experience any malfunctions with the exception of the problem with the trigger as described above, and failures to function with the legacy 20-round GI magazine and the TAPCO polymer 30-round magazine.

I have owned the GI mag since the early 1970s, and the spring has become so weak that it simply could not keep up with the gun’s cyclic rate. Because the feed lips and body are still in good condition, I’ll order a 20-round Magazine Rebuild Kit from Brownells for this mag.

The TAPCO magazine either seats ever so slightly lower in the magazine well, or the dimensions at the top of the magazine position the cartridges slightly lower. The tips of approximately one-third of the bullets attempting to chamber would strike the flat area just below the feed ramps and hang up. It goes without saying that a 33% failure rate is unacceptable. In fairness to TAPCO, these were early production mags, and I do not know if any changes have been made to later versions.

All other magazines worked as advertised.

New EOTech Extreme EXPS buttons are now located on left side of the sight.

SUMMARY

I would humbly offer that the following changes/additions be made to the Para TTR:

1) The annoying gap between the rear of the trigger guard and the pistol grip is present, which caused a blister on the middle knuckle of my middle finger during the evaluation. A better way to go is the enhanced trigger guard from Magpul and other manufacturers. It will fill this gap.

2) No rail covers were included with the carbine. This may be of little consequence in a rifle that is used for target practice or weekend competitions, but without covers of some type, the rails can become easily damaged in a gun that sees hard use.

While but a single example, the test gun ran very well and had acceptable social accuracy with all ammunition used in it. If magnifying optics were used, accuracy would no doubt be even better.

For end users who operate in and out of vehicles, the folding stock may be a major selling point. The suggested retail price of the Para TTR-XA is $2,397.00.

SOURCES:

Para USA, Inc.

Dept. S.W.A.T.

10620 Southern Loop Blvd.

Pineville, NC 28134

(704) 930-7600

www.paraord.com

Black Hills Ammunition

Dept. S.W.A.T.

P.O. Box 3090

Rapid City, SD 57709-3090

(605) 348-5150

www.black-hills.com

Bravo Company Mfg.

Dept. S.W.A.T.

P.O. Box 341

Hartland, WI 53029

(877) 272-8626

www.bravocompanyusa.com

Brownells Inc.

Dept. S.W.A.T.

200 South Front Street

Montezuma, IA 50171

(800) 741-0015

www.brownells.com

Fusil-USA, LLC

Dept. S.W.A.T.

113 N. Lively Blvd

Elk Grove Village, IL 60007

(847) 437-0100

www.fusil-usa.com

Hornady Mfg. Co.

Dept. S.W.A.T.

Box 1848

Grand Island, NE 68802-1848

(800) 338-3220

www.hornady.com

L3 EOTech, Inc.

Dept. S.W.A.T.

1201 E. Elsworth Rd.

Ann Arbor, MI 48108

(734) 741-8868

www.L-3Com.com/Eotech

Lancer Systems

Dept. S.W.A.T.

7566 Morris Court, Suite 300

Allentown, PA 18106

(610) 973-2600

www.lancer-systems.com

LaserLyte

Dept. S.W.A.T.

101 Airpark Rd.

Cottonwood, AZ 86326

(928) 649-3201

www.laserlyte.com

Magpul Industries Corp.

Dept. S.W.A.T.

400 Young Court

Erie, CO 80516-8440

(877) 462-4785

www.magpul.com

SureFire, LLC

Dept. S.W.A.T.

18300 Mount Baldy Circle

Fountain Valley, CA 92708

(800) 828-8809

www.surefire.com

TangoDown

Dept. S.W.A.T.

1588 Arrow Highway, Unit F

La Verne, CA 91750-5334

(520) 888-3376

www.tangodown.com

TAPCO

Dept. S.W.A.T.

P.O. Box 2408

Kennesaw, GA 30156-9138

(800) 554-1445

www.tapco.com

The Beta Company

Dept. S.W.A.T.

2137B Flintstone Drive

Tucker, GA 30084

(800) 669-2382

www.betaco.com