Ten years ago, when an acquaintance suggested that there was a difference between the .223 Remington and 5.56x45mm NATO calibers, I didn’t believe it. I was sure he was either confused by the nomenclature or had been taken in by some kind of advertising disinformation whose perpetrators would somehow benefit from making people uneasy about one cartridge having two names. I try these days to be more open-minded. Listening to everything doesn’t mean believing everything, but ten years on, I am more mindful of the fact that I don’t know all there is to know. I expect I never will, but it won’t be for lack of trying.

The condensed story is this: the .223 Remington cartridge is indeed the commercial version of the 5.56 NATO cartridge (the reverse is actually more factual if one looks at the chronology of the cartridge’s development). But there are differences between the two. Some of the differences between the two cartridges are very subtle. Comparing cartridge specs, dimensionally, some of them amount to only a few thousandths of an inch. Other differences are simply the presence of military specification cartridge features that usually are not present in commercial loadings, such as crimped-in primers and waterproofing measures. There is a difference in pressure and velocity specifications, which is a critical issue, since it can become a safety concern. Finally, the respective chamber dimensions are identical in some areas, but quite different in others. It is important to understand those chamber differences and how they can interact with the higher pressures of the NATO loading. That is the main focus of this article.

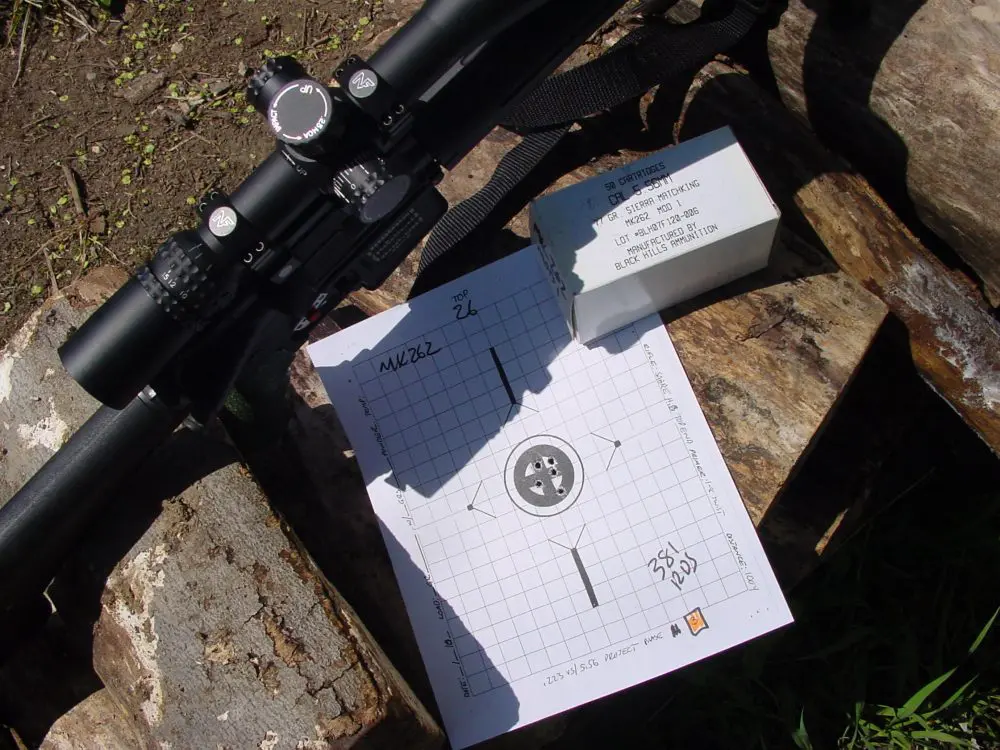

Great news from the Department of Good Stuff For The Troops: issue Mk262 Mod 1 ammo from Black Hills, featuring cannelured 77-gr. Sierra Match King bullet, is very accurate. Five into under an inch at 100 yards.

Another “making a long story short” bit of info for those who may not be interested in delving deeper into the technical details of all this: Do not fire 5.56 military or milspec ammo in .223 chambers! If you don’t want to take my word for it, I won’t be offended (see paragraph one), but you can find the same basic statement from ammunition manufacturers in any number of places. For example, it was printed on the boxes of some of the Hornady ammo I used in accuracy testing for this article. Winchester’s Law Enforcement website has this to say: “The 5.56mm military cartridge fired in a .223 Remington chamber is considered by SAAMI (Sporting Arms and Ammunition Manufacturers Institute) to be an unsafe ammunition combination.” This combination also has made the “don’t do this” list on the SAAMI website (www.saami.org). I know lots of folks who have gotten away with it, especially since over the years, military surplus ammo has been relatively plentiful and inexpensive (a period now known as “the good old days”). I’ve done it myself and still have all ten fingers and both eyes—but I know better now and I avoid it.

Table of Contents

CHAMBER DIFFERENCES

A comparison of some chamber dimensions is in order, but first some of the terminology needs to be laid out and understood. I’m sure S.W.A.T. readers know that headspace refers to the depth of the chamber, specifically, the part of the chamber that stops the forward movement of the cartridge. In a bottlenecked cartridge like the 5.56, this is done by the shoulder of the cartridge meeting the corresponding shoulder in the chamber; obviously some clearance must be built in. Not enough clearance and the round will not permit the bolt to lock into battery; too much clearance and all sorts of things can happen, including poor accuracy and case separation (the case stretches so much it breaks in half).

Chamber casts from Sabre Defence barrel before reaming (top) and after. Dave Manson chamber reamer at bottom.

Neck diameter is the part of the chamber that the cartridge neck fits into.

Freebore is very important to us. It is the part of the chamber just forward of the neck—the part that the bullet enters into as the cartridge is seated in the chamber. It stands to reason that it has to be just a little larger in diameter than the bullet. That diameter depends, to varying degrees, upon exactly which style of chamber we are talking about.

Throat is the tapered area starting at the end of the freebore. It starts at the diameter of the freebore and tapers down and extends into the rifling. It eases the bullet into the rifling as it leaves the cartridge. The rifling can’t begin with a sharp edge, or it would cut the bullet into shape, where we want it to be gently and somewhat gradually squeezed into the lands, conforming to the inside shape of the barrel.

The differences between the .223 SAAMI-spec chamber and the 5.56 NATO chamber start at the base of the cartridge and go all the way to the throat. Base diameter and the diameter where the shoulder starts are, as expected, tighter in the .223 than in the 5.56. In some of the more truly target-oriented versions of the .223 chamber, such as the .223 Compass Lake—known for building high-end target AR-15s—these rearward dimensions are tighter still, but only by a few thousandths of an inch. Shoulder angle (23 degrees) and the headspace dimension, expressed as the distance from the bolt face to a datum point on the shoulder, are the same in every variant of the chamber that I’ve seen except one. Forward of the shoulder is where things start to get really different.

One more thing: the .223 Wylde Chamber.

Several manufacturers are using a chamber designed by Bill Wylde. By virtue of the fact that it was designed for target competition, allowing room in the freebore for very long-seated, long-ogive bullets, it is actually more “generous” than the 5.56 in some dimensions.

I don’t have personal experience with this chamber, but looking at the dimensions, I would have to conclude it might indeed be a viable alternative to the 5.56 that ought to give a theoretical edge in accuracy due to its tighter freebore dimension, which would tend to pre-align the bullet better with the bore.

Reaming the chamber prior to Phase III grouping.

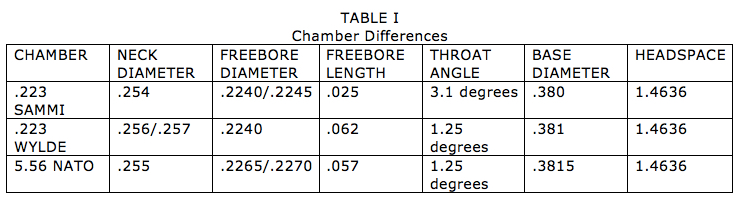

The differences between the three chambers can be seen in Table I.

As can be seen in the table, the 5.56’s freebore length is more than twice as long, and the angle of the throat is less than half that of the .223, so the “squeezing in” of the bullet into the rifling occurs much more gradually in the 5.56 chamber.

A perfectly logical question at this point would be, why are there even two different versions? Why all the subtle differences? Why didn’t “they” just standardize on one set of dimensions? The short answer, the long answer, and the conventional wisdom, are “accuracy.” Tighter chambers are traditionally held to give better accuracy than looser ones. Looser ones will tend to enhance reliability, by virtue of simply giving more space to accommodate powder residue build-up, foreign material, and out of spec or beat-up ammo. Tight chambers? Bench rest competitors—the guys who go home disappointed and out of the money if they didn’t put ten shots into a group smaller than the caliber they’re shooting—will go to extravagant lengths to achieve a close match between the cartridge case and the chamber. They will turn the case neck of each case for perfect sizing and concentricity. They will resize only the neck of the case when reloading it, so that the body can stay as large as possible and still fit into the chamber.

In addition, freebores will be a nearly no-clearance fit to the bullet diameter to give the bullet a perfect, no-wiggle start into the rifling. Bullets will be seated out longer so that they are just touching the rifling lands toward the end of the throat, so they don’t have to “jump” into the rifling. Flash holes will be carefully reamed for uniformity. With chambers so tight, the brass is flexed very little in firing and resizing, so a benchrester may shoot a whole season of competition with 50 or fewer cases thus prepped.

The above just doesn’t work in the context of a patrol rifle, a fighting gun of any sort, or really, even a plinker. Of course, more accuracy is always desirable, and AR-15s can be incredibly accurate. Many a “10” ring and “X” ring have been perforated at 600 yards in NRA High Power shooting. For anything other than a true target rifle, however, reliability trumps accuracy. How much is accuracy really affected by going from a .223 chamber to a 5.56? I have some answers, but first, more on reliability.

Third and final go with the reamer, showing shavings from removal of metal in freebore and throat of chamber.

THE PROBLEM

Broadly speaking, milspec ammo is hotter than commercial-spec ammo by about 200 feet-per-second (fps). Although SAAMI protocols for measuring chamber pressure are different from those used to check military ammunition, which makes an exact, direct comparison less than simple, milspec 5.56 ammunition can be as much as 5,000 PSI over the .223’s max average pressure spec of 55,000 PSI. That’s only about a 9% increase, and the word “only” works allright until we fire that hotter ammo in the .223 chamber. Now, the short freebore and abrupt throat essentially try to put a halt to the bullet’s forward travel just as it is getting started, and just as the chamber pressure is building exponentially and approaching its peak. This causes a pressure spike that really starts to stress things. Is it going to blow up your gun? ARs do go “kaboom” on occasion. I have never been present for such an unhappy event and can’t say that I truly know of any that were proven to have happened as a result of firing 5.56 ammo in a .223. But I think it’s safe to say that at the very least, firing mass quantities of 5.56 in a .223 chamber will shorten the service life of something in the rifle.

What it will do is overstress the weak link in the chain—the cartridge case. The result can be popped primers. “Popped” seems to be the common term, although it is something of a misnomer. This is when primers fall out of a fired case as it is ejected, due to an overpressure condition having actually expanded the entire case head and, along with it, the primer pocket. When the primer pocket gets bigger than the primer, even crimped-in primers will come out. I have measured the primer pockets of 5.56 cases that lost their primer somewhere between ejection and Mother Earth. Where the government drawing for the 5.56 case calls for a pocket diameter of .1738/.1745, these primerless cases have pockets that measure as large as .180. Primers usually measure about .175/.1755 for a nice press fit in a to-spec primer pocket, so it’s no wonder that they fall free from a .180 hole.

Some cartridge differences between commercial and milspec ammo. Lower left: Federal XM193 has waterproofing sealant and annular primer crimp to help primer stay in place. Upper left: Remington commercial round has neither. Upper right: Spanish 5.56 NATO has sealed primer and three stab crimps. Lower right: XM193 case that has lost its primer upon ejection. Primer pocket is deformed to slightly oval shape, several thousandths of an inch larger in diameter than the primer it once held.

But who really cares about primers falling out, other than maybe handloaders who can’t re-use brass with oversize primer pockets? It’s all about where the primer goes, and rest assured that Murphy is right there, ready to help any wayward primer with an easy-to-follow holiday map into the very bowels of your rifle. Favored destinations include:

Wedged under the trigger. Result: fire control is out of commission until trigger group is removed so primer can be shaken out.

Lying in barrel extension. Result: bolt cannot go into battery until spent primer is shaken out or coaxed out with some kind of probe.

Caught between bolt carrier body and upper receiver. Result: bolt group is wedged to a halt until upper and lower receivers are separated and carrier is pounded out, freeing primer.

It is less common, but more vexing, when the primer’s anvil becomes separated from the cup and winds up in the carrier key spigot, preventing it from telescoping completely over the gas tube. Result: bolt group held out of battery while you check for everything but this unbelievable feat of orienteering by a piece of metal smaller than some mosquitoes. And when you do find it, you practically need a custom-made dental pick to get it out, since it’s been really hammered into place by the end of the gas tube!

There are probably some variations on this I haven’t seen, but obviously it does matter if primers are falling out. I suppose some do fall out harmlessly, but I’ve yet to find a primerless empty on the ground in routine policing-up of brass. There are other factors that can contribute to the pressure spike, too.

You drive to the match/class/gunfight with your ammo in the trunk. It’s the hottest, sunniest summer day in three years. You open the trunk and let your ammo soak up another two hours’ worth of direct sunlight. It burns your fingers as you load it into magazines. That ammo is going to have higher pressure than if it had been a chilly, overcast day in November. Or, let’s say you’ve just fired two magazines as fast as you could. You pause for a minute. The round in the chamber is absorbing the heat from a barrel that is now way too hot to touch. When you fire that round, it will generate higher pressure.

Short lengths of barrel, partially chambered and sectioned to illustrate much longer freebore and more gradual throat angle of 5.56 NATO chamber (right). Short freebore and abrupt throat of .223 SAAMI-spec chamber (left) can cause pressure spike when firing hotter 5.56 ammo.

ACCURACY TESTING

To test the chamber’s effect on accuracy, I took a Nightforce NXS 3.5-15X56 scope and parked a new AR-15 top end from Sabre Defence—their Heavy Bench Target model—underneath it. It is a 24-inch stainless-barreled unit with a 1:8 twist and a .223 chamber. To make a complete rifle, I used the bottom half of my NRA High Power match rifle, which has an excellent trigger. To confirm the chamber configuration, I made a cast of it using Cerro-Safe from Brownells, and indeed it was a perfect SAAMI .223 chamber.

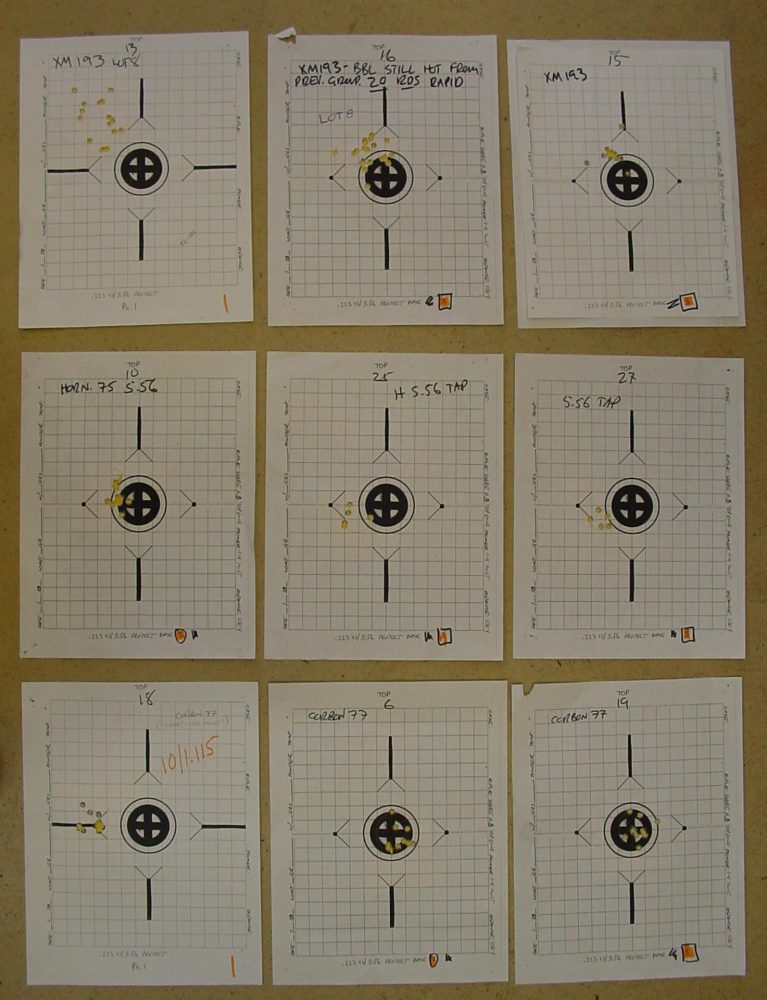

I amassed a collection of ammo types that I felt represented some options likely to be used in a more duty-oriented gun, including Special Purpose Rifles (SPR)/precision role. As training ammo I included Federal XM193 55-gr. FMJ, Spanish SS109 62-gr. FMJ, and some Israeli “SS109 Compatible” ammo (62 grains but no steel penetrator). Street/duty ammo included Federal Tactical with a 62-gr. bonded bullet, CorBon DPX 62-grain loads (all copper/no lead bullet), Winchester Q3283 with the Nosler 60-gr. partition bullet, Black Hills Mk 262 Mod 1 (with cannelured 77-gr. Sierra Match King), Hornady’s 62-gr. penetrator load, and Hornady’s 5.56 TAP 75-gr. and .223 FPD 75-gr. loads. Except for the last two, these are restricted or somewhat restricted to LE/military sales. For precision ammo, I used Hornady Match 75s, Federal Gold Medal Match 77s, CorBon 77s, and Black Hills .223 77s. I believe all three of the 77-gr. loadings are using the Sierra Match King.

After a break-in period for the barrel consisting of about 50 rounds and 25 cleanings, I shot groups in three phases. Phases I and II were with the original .223 chamber. The only difference between I and II was that after firing Phase I, I discovered what I felt was a non-textbook crown at the Sabre’s muzzle. Although I had no complaints at all about Phase I groupings, I was curious to see if there would be any difference in accuracy with the “textbook” 11-degree crown, and also to see if it would help the varied loads shoot closer to each other. There was no change, confirming that concentricity is more important than configuration in a crown. Dismounting the scope, unbarreling the upper, recrowning, reassembling and remounting the scope had almost no effect on the point of impact (POI), either.

Hornady ammo used bullets. Left to right: 62-grain “Barrier” features thicker jacket, harder core. 5.56 bullet has longest shank, bluntest ogive. Match bullet: longer ogive, no cannelure, FPD is almost a blend of the first two. 5.56 and FPD bullets are slightly rolled in at tip for better feeding. Note wording on 5.56 box: “NOT FOR USE IN.223 CHAMBERS.”

THE VERDICT

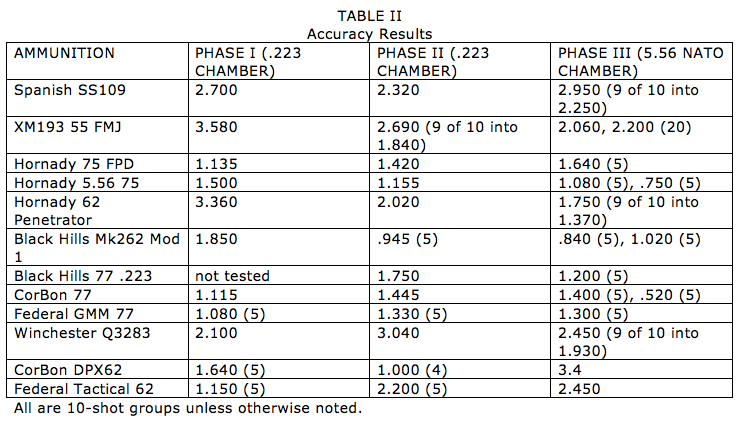

Phase III groups were fired after reaming the chamber to 5.56 NATO—actually a rather generous 5.56 NATO, using a reamer made “to the high side.” My two half-days at the range can be summed up like this: after shooting 53 groups from a bench at 100 yards using a Harris bipod, more than half of which were 10-shot, not five-shot groups, I concluded that there was no difference in accuracy, overall. I acknowledge that this was one test with one guy and one rifle, and does not constitute anything near a long-term test conducted to a high scientific standard, and that a real statistician would rightfully declare the results as statistically inconclusive. However, viewing the results, I still feel I can unequivocally state that reaming the chamber to the larger, looser dimensions did not cause accuracy to “go all to hell.” A few ammo types shot larger groups after reaming. Many were remarkably similar before and after. The majority were actually better, but anyone who has shot 10, 10-shot groups in an afternoon, each fired with the same load under the same conditions, knows that they will probably not all be the exact same size. Again, statistically this test may not pass muster, but a degradation in accuracy would have shown itself in the 19 Phase III groups I fired. Some sample results are shown in Table II.

I carefully inspected all my empties after each phase and, somewhat to my disappointment, no primerless cases were found. On the other hand, the weather was in the high 50s and, of course, firing was slow and purposeful.

How do you know which chamber you really have? That can be a tough one. You might have a receiver marked one way that has had an upper or barrel installed with something else. You may have a barrel marked “5.56 NATO” when it really is not. Since many manufacturers don’t make their own barrels—and as I am convinced that many don’t gage the chambers of incoming barrels—the barrel marking is not necessarily the last word. Worse, it seems as if some manufacturers don’t understand or appreciate the differences, and a few have been known to get elusive, defensive and downright snippy about it. A chamber cast or visual check with a bore scope are two tedious, expensive ways to be sure.

ACCURACY TEST HARDWARE AND AMMO

Sabre Top End

Sabre is one of the few AR-15 manufacturers that makes its own barrels. The heavy 24-inch barrel was fluted and free floating with a flat-top receiver. Sabre also produces bolts and carriers; those that came with this unit were of top quality. This is not surprising, as Sabre produces M2 .50-caliber machinegun receivers, barrels and other components, and has made complete M2s in the recent past. They also produce M60 and M134 Minigun replacement barrels for the government. One would expect them to have a good handle on “milspec” requirements.

Nightforce Scope

I’m no glass expert. But the Nightforce line is some impressive gear, and when I saw the Army Marksmanship Unit using them at Camp Perry, I figured I’d better put Nightforce on my map. The NXS 3.5-15X56 I used had their NP-R1 ranging reticle. While the capabilities of the reticle were rather wasted, what with all my shooting being at 100 yards, its very fine lines and perfect image made precision alignment easy. Subsequent experimenting with dismounting and remounting the scope with insignificant to no change in POI bore out my impression of the Nightforce mounting system as being very well made and repeatable. One of my pet peeves on guns and accessories is sharp edges and burrs. The Nightforce Unimount was exquisitely machined, deburred and rock-solid.

Ammunition Used

Thanks to Black Hills, Hornady and CorBon for providing ammo for testing. All three are producing .223 and/or 5.56 loadings with 75- or 77-gr. bullets—which in my experience and opinion are the long-awaited perfect mate to this cartridge in many ways, as long as the rifle has a 1:8 or faster twist. It seems like just about any bullet of this weight shoots well.

It is interesting to note that, while Hornady offers 75-grainers in Match, FPD (For Personal Defense) and 5.56 flavors, the three bullets are different. The match bullet is an un-cannelured HP with the longish ogive one would expect in a long-range target bullet. The FPD has a shorter ogive, and the 5.56’s is slightly shorter still. Both have commensurately longer bearing surfaces, with the hollow-point tip being ever so slightly rolled over, I presume for better feeding. Both feature a cannelure. To my surprise, both the FPD and 5.56 out-grouped the Match at 100 yards, but I would expect the Match to outperform the other two at longer ranges. Hornady’s excellent 75-gr. A-Max polymer-tipped target bullet in .224 diameter is, unfortunately, too long to load in .223/5.56 unless they are left so long that they cannot fit in the magazine. Plenty of people in the High Power game use them just this way, single-loading them for the 600-yard, slow-fire prone event.

The CorBon 77-gr. loading is new and very accurate, easily giving the Federal Gold Medal Match a run for its money.

The Black Hills Mk262 Mod 1 was current military-contract ammo meant mainly for the Special Purpose Rifles being used in the war zones. It is a perfect complement to those highly accurized M16s, grouping more like a target load than a combat load out of the Sabre.

In summary, despite what one may read on the Internet, the 2.23 Remington and the 5.56x45mm NATO cartridges are not one and the same, and the manufacturers marking on the barrel has been shown to not always be accurate. It is responsibility of the individual to make sure his weapon/ammunition is, in fact compatible.

[Editor’s note: While Ned Christiansen is too modest to blow his own horn, he makes an excellent Neck and Throat Reamer to turn .223 chambers into true 5.56 chambers. At $240 it is not inexpensive, but it is surely less than the cost of a new barrel wrecked by firing the wrong ammunition—not to mention possible injury to the shooter. The reamer is available at www.m-guns.com.]

SOURCES:

Sabre Defence Industries, LLC

Dept. S.W.A.T.

450 Allied Drive

Nashville, TN 37211

(615) 333-0077

www.sabredefence.com

Black Hills Ammunition

Dept. S.W.A.T.

P.O. Box 3090

Rapid City, SD 57709-3090

(605) 348-5150

www.black-hills.com

CorBon

Dept. S.W.A.T.

P.O. Box 369

Sturgis, SD 57785

(800) 626-7266

www.corbon.com

Hornady Mfg. Co.

Dept. S.W.A.T.

Box 1848

Grand Island, NE 68802-1848

(800) 338-3220

www.hornady.com

Lightforce USA, Inc.

Dept S.W.A.T.

1040 Hazen Lane

Orofino, ID 83544

(208) 476-9814

www.nightforceoptics.com