Growing up on farms and ranches, I learned the importance of a good, sharp knife. A sharp knife is a lot safer than a dull knife, because with a dull knife, you may be sawing more than slicing. Pushing so hard on the knife, you might slip and cut yourself.

For years, I watched my Grandpa Denny put a razor edge on his knives and those of other family members with a Spyderco Tri-Angle Sharpmaker. Several years back, he gifted my Dad a Sharpmaker for Christmas. For my birthday this year, Grandpa gave me my very own Spyderco Sharpmaker, making three generations of our family who use one. Let me tell you more about this great product.

Although Spyderco is known mostly for knives, the Sharpmaker was actually the company’s first product. As Spyderco says, “First we made things sharp, then we made sharp things.”

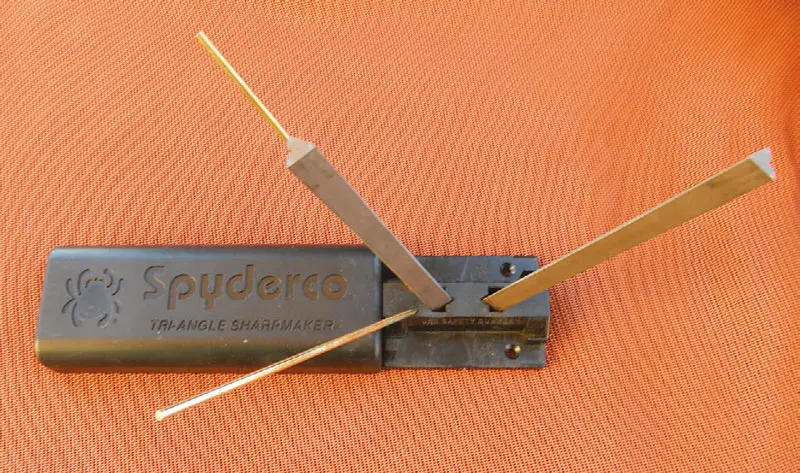

The Spyderco Sharpmaker comes in a hard ABS plastic protective case. Nestled inside you’ll find four ceramic triangular- shaped stones. Two of the stones are gray and two are white. The stones are technically a synthetic sapphire and so hard they can remove any metal, even from a hard file.

The gray stones are the starting stones that put a good edge on your knife, while the white are the finishing stones that make your knife razor sharp. Also inside the case are two brass rods that function as protective safety handguards. You should always use them, to avoid accidentally cutting yourself if you slip.

The lid of the case does double duty, snapping into the midway point of the base and serving as an extension for better control.

There are two keyed slots on both sides of the base with different angles that the stones sit at: 30 and 40 degrees. Spyderco knives come from the factory with a 30-degree angle. Spyderco is one of the few knife companies that pay attention to the 30-degree edge, but they recommend using the 40-degree stones for most uses, because a knife with a steep, sharp edge will become dull faster.

To begin sharpening, insert the brass safety guards and place the gray stones in the 40-degree slots with the corners of the triangles pointing inward. Holding the knife blade straight up and down, and starting at the back of the blade, draw the blade along the stone all the way to the tip for about 30 strokes on each side. Then replace the stones in the keyed slots with the flat sides facing inward and apply another 30 strokes to each side.

This will give the knife a good utility edge that, on a quality knife, should last for some time. For an even sharper, professional edge, repeat the above using the white stones.

The ceramic stones actually remove metal and after awhile, the edge will work up into the thicker part of the blade using the 40-degree slots. And so, while still sharp, there will be more drag on the blade as you cut.

Spyderco recommends placing the stone in the 30-degree slots about every tenth time you sharpen your knife. This will “back bevel” the blade and break down the shoulder created by sharpening at the 40-degree angle.

Can knives with serrated edges be sharpened with the Sharpmaker? You bet!

Using just the corner edge of the stones, with every five or so strokes on the flat side to remove any burr that may have arisen, serrated blades can be returned to an edge equal to or better than how it came from the factory. Go slowly to make sure you don’t skip over any serrations.

A groove on each stone can be used for sharpening anything with a point, such as an awl, darts, and fishing hooks.

On the end of the base is a single keyed slot that holds one stone. This slot positions the stone at 12.5 degrees and is used for sharpening scissors. As with sharpening a knife, start with the corner edge of the stone and hold the blade of the scissors straight up and down. Starting at the back, pull it across the stone to the tip. Repeat the process on the other blade, then progress to the flat edge.

If you turn the base upside down, you will find two slots that hold each stone side-by-side. This allows the Sharpmaker to be used as a bench stone to sharpen tools such as a planer blade.

Holding the stone like a file, you can use the corner to remove burrs from the inside of a Phillips-head screwdriver. Use the flat side to straighten the tip on a flat-head screwdriver.

Clean the sharpener after it starts to collect metal—when the white stones have turned almost black. The cleanup process is very easy. Put the Sharpmaker’s stones in water and use a plastic scouring pad and powdered abrasive cleaner such as Comet and scrub them to remove accumulated metal and let air-dry, or you can put them in the dishwasher.

Spyderco includes a video with step-by-step instructions showing how to set up and use the Sharpmaker and how many different things it can sharpen.

I have used the 40-degree stones to put a utility edge on every knife in the house. The only drawback is that I no longer have any hair on either arm from testing how sharp the blades are. I have even sharpened the hand axe I take camping.

If you need to put a good edge on a knife—and we all do— the Spyderco Tri-Angle Sharpmaker is a necessity. Suggested retail price is $104.95, and worth every penny.