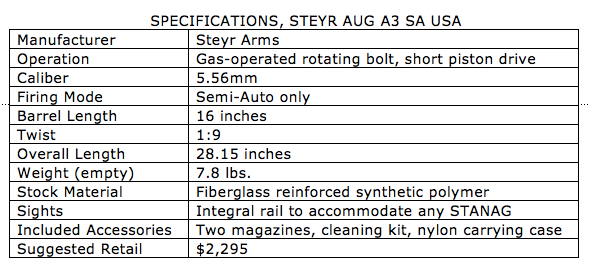

Fans of the Steyr AUG have reason to be excited.

AUGs were previously available in the United States only in pre-ban form, which for the most part were manufactured prior to the Import Ban of 1989. That ban was permanent. Even though the so-called Assault Weapons Ban expired in 2004, no new Steyr AUGs could be imported from Austria for civilian sales. Now Steyr is manufacturing the AUG in the U.S.

Shortly after the Assault Weapons Ban expired, Steyr began quietly searching for the appropriate U.S. company to partner with to produce AUGs for American sales.

In doing so, they would have to comply with Title 18 of the U.S. Code (18 USC), Chapter 44 Section 922, which prohibits assembling any gun similar to a gun on the 1989 list of guns banned from import if the assembled gun uses any more than ten imported parts. This meant that Steyr’s U.S. partner would have to provide the bulk of parts as well as assembly.

Right side of AUG A3 SA. Photo: Jessie Indracusin

After carefully scrutinizing several potential partners, Steyr selected Sabre Defence. Thus began years of development, which involved flying engineers and production crews from both countries to visit people and facilities on opposite sides of the Atlantic.

Sabre Defence is known for their line of ARs as well as for producing barrels for everything from miniguns to .50-caliber machineguns. This makes them a natural fit, since one of the components that they would be producing for the AUG was the barrel and all the subassemblies that go into it, like the gas piston, muzzle break, and regulator.

While not hammer forged like the original AUG barrels from Austria, Sabre barrels are specially heat treated and made from the same Chrome Moly-Vanadium alloy that they use in the .50-caliber machinegun barrels they provide to the U.S. military. Steyr USA believes these to be just as good, if not better, than the hammer-forged barrels that are used in the Austrian-made AUGs. Like the originals, the barrels produced by Sabre feature a chrome-lined bore and chamber.

Virtually all parts are interchangeable between the new American-made AUG and its Austrian-produced brothers. The American-made AUG, fully designated the Steyr AUG A3 SA USA, is a semi-auto version of the Austrian-made select-fire AUG A3. It incorporates some of its Austrian progenitor’s features, namely the bolt release on the left side of the stock just north of the mag well, a Picatinny rail for mounting optics on top of the receiver, and another rail on the right side of the receiver for mounting additional accessories. It dispenses with the rails that the Austrian AUG A3 mounts below the barrel, just above its vertical foregrip.

Close-up showing new bolt release. Photo: Jessie Indracusin

The American AUG A3 comes with a 16-inch barrel. This gives the AUG enough barrel length to be legal and to take advantage of the 5.56mm’s ballistics, while keeping the gun’s overall length down to a compact 28.15 inches. While the original military AUGs and the semi-auto models imported into the U.S. sported 20-inch barrels, 16 inches later proved to be a more popular length, since it makes maximum use of the bullpup’s compactness. Barrels can be switched in seconds without the use of tools by disengaging a spring-loaded takedown switch and using the vertical foregrip to twist the barrel out from the receiver. The barrel can be put back in place with no change in zero.

The only component that is not interchangeable is the stock of the older models. They cannot be used on the new model because they have a hump that interferes with the new top rail. This is unfortunate, because there is a Steyr stock available that fits the older AUG that accommodates AR mags. This stock comes with its own trigger group to insure that the bolt will lock back after firing the last round from an AR magazine. (If you ever mistakenly put this trigger group into any stock other than one designed for AR mags, you will convert that gun to a single-shot weapon until it is replaced with the correct trigger group.)

The new AUG A3 weighs in at 7.8 pounds empty. However, it feels lighter than this because most of the weight is between the dominant hand and the body, giving it a center of gravity farther back than most long arms.

AUG A3 SA disassembled. Photo: Jessie Indracusin

The AUG employs a short stroke gas piston operating system. When fired, it directs propellant gases through the barrel’s gas port into the gas cylinder on the right side of the barrel. These gases drive the piston rearward against the right guide rod, which cycles the bolt carrier and bolt.

Like the original, the new American-made Steyr features a three-setting adjustable gas system. The first setting is for normal ammo. The second one is for use with either weak ammo or when the gas system is very dirty. As a default, the gun should be left on the first/normal setting. The third gas setting, which is designed for rifle grenades, cuts off the gas from the action and directs it toward the muzzle to best propel the grenade.

Our test gun’s serial number indicated that it was the 25th one built on the new U.S. production line. It arrived from the manufacturer with a standard package of accessories, which includes a padded nylon carrying case, cleaning kit, sling, and two U.S.-produced magazines.

As soon as I tried these magazines in the gun, I noticed that they would not lock into the magwell without a hard whap on the bottom. The result was the same in my own Austrian-built AUG A2. This is a problem, because slapping the bottom of a magazine can make the top round pop out into the open chamber and cause a double feed when the bolt is released and it picks up an additional round from the magazine.

In my experience, AUG mags are far more vulnerable to this than AR mags. This is why it’s always best practice to tilt the AUG to the side so that its ejection port faces the ground before releasing the charging handle. This allows any loose rounds in the chamber to fall out. The Australian Army Manual of Land Warfare (Volume 4, Small Arms) emphasizes this point.

AUG A3 SA, AUG A2, and AR with 10.3-inch barrel with stock collapsed for size reference.

When I tried my European-made AUG mags, they slid easily into the new gun. A call to Steyr USA revealed that they had changed the American-made magazines somewhat to insure a tighter fit. In comparing them to my Austrian-made magazines, I noticed that the American-made mags had thicker feed lips. Luckily, Austrian-made magazines are readily available.

The AUG A3 incorporates several new features, both internally and externally. Unlike previous versions that use a tulip-shaped flash hider, the A3 features a muzzle brake. While I normally eschew muzzle brakes on .223s, I noticed a big difference in controllability with full-auto fire when I tried the new AUG’s barrel in a friend’s older select-fire AUG.

The AUG A3 features a new bolt release located on the left side of the receiver. This new addition is solidly constructed and low profile, yet positioned in a perfect spot for easy actuation after inserting a fresh magazine. Previous AUGs depended on racking the charging handle to chamber the first round from a newly inserted magazine when the bolt is locked back after firing the last round of the previous magazine.

Given that the ejection port of the AUG is far back, it cannot be fired from the left shoulder without ejecting hot cases into the shooter’s face. Like previous Steyr AUGs, the new gun has ejection ports cut on both sides of its stock to allow it to operate with a left-handed or right-handed bolt. A removable lid made of plastic backed by metal on the inside is used to cover the side not in use. I’ve taken the precaution of putting tape over the removable lid, since I’ve seen these come loose.

The carbines come from the factory set for right-handed use. If you wish to set the gun up for left-handed use, you need to purchase a left-handed bolt.

Another area that I applied tape to is on the stock directly behind the ejection port, since ejected cases sometimes smack into this area, eventually resulting in dings and gouges to the stock’s surface.

The AUG A3 comes with an integral Picatinny rail on top of the receiver to allow mounting aftermarket optics. This makes sense to the manufacturer from an economic standpoint, since it makes it easier and less expensive to build and sell the gun. It also makes sense to many buyers, who usually want to choose their own optic.

Optics have come a long way since 1977, when the Steyr AUG debuted. The original AUG was revolutionary in that it incorporated an integral 1.5X optical sight. This sight used a thick black circle as its reticle. Referred to as the “donut of death,” the inner part of the reticle was about as wide as a man’s shoulders at 100 yards. This circle was used as an aid to range finding, with the target typically being framed in the center of the circle at ranges where the gun is dead-on. Where you frame the target in the circle depends on the distance.

Jim Smith shooting AUG equipped with Leupold CQT optic and Digital Kinematics electronic shooting training device on side rail.

Some later versions of the AUG incorporated a sub-MOA dot at the center of the circle to serve as a more precise aiming point.

The A2 version of the AUG added a thin crosshair to the center of the donut. This was the first AUG to feature a removable optic that could be replaced by a Picatinny rail to allow mounting of additional optics. A very small number of A2s were imported, while others came into the U.S. as part of a program that sent older AUG receivers from the U.S. to Austria for replacement by A2 receivers.

For an optic, I chose an Aimpoint T1 Micro with a LaRue Tactical 660HK quick-detachable mount. While I used a shorter LaRue mount for the same optic on my AUG A2, which has a higher rail, I found that this mount was far too short for the new A3, as I had to really press my face into the stock to be able to pick up the red dot. However, the LaRue 660HK mount, which is actually designed for an HK416, proved to be the perfect height for the new AUG A3.

Internal changes are also present. The firing pin now comes standard with a captive spring, a feature present in some earlier AUGs. This prevents an issue with frequently rechambered rounds failing to detonate. This has been observed mainly in AR-15 and M16 variants and has been traced to repeatedly chambering the same round. This is caused by the AR-15’s floating firing pin lightly tapping the primer.

With repeated rechamberings and the attendant taps, the primer compound gets crushed, resulting in failed ignition. In some cases the indentation may deepen enough to put that spot out of reach of a firing pin strike. Thus chambered rounds should be checked for indentations on the primer, and if these indentations exist, they should not be used for duty or defensive purposes.

Another internal change that is unique to the AUG A3 is a new cocking piece that locks the rear of the firing pin in place and prevents it from rotating to an unlocked position. The normal AUG firing pin is removed from the bolt carrier by pushing it in and twisting it 90 degrees counterclockwise.

The only time I ever saw one come out of a gun while firing was when using some overpressure, reloaded ammo. I stopped using this ammo immediately, as it was so overpressure that it frequently split the shell casings. Noted firearms instructor and AUG expert Giles Stock reports witnessing this phenomenon only twice in over 20 years. But this modification eliminates the possibility. This new locking cocking piece, along with the firing pin and its captive spring, will be available as part of an upgrade kit for older AUGs.

The gun arrived from the factory with a charging handle that was unbelievably stiff to retract, to the point that I contacted the Steyr representative. He informed me that it would take use to work itself in. This proved to be true to some extent, but not as much as I would have liked. At the end of the thousand-plus round test, it had improved considerably but it was still a strain to cock the gun.

The trigger pull of the new AUG A3 came in at around five and a half pounds. Although still a bit long and mushy, it was a vast improvement over the earlier generation semi-auto AUGs imported into the U.S., which sported triggers that might run as much as twice this.

The gun provided the type of reliability that I’ve come to expect from Steyr AUGs. It performed without a malfunction for the entire test. Sabre’s reputation for making fine barrels definitely showed. When fired from the bench with the Aimpoint T1 at a target at 50 yards, it was possible to shoot postage-stamp sized five-shot groups if I did everything correctly and consistently. The gun seemed to shoot best with Black Hills 55-grain loads. I tried other brands of ammo of the same weight, but did not get groups nearly as tight.

To get an idea of what the gun would do at longer ranges, we visited Jim Smith of Spartan Tactical (see “Stretching the Distance,” S.W.A.T., November 2008) at his training facility in Jacksborro, Texas.

We slapped a Leupold CQT 1-3X optic on and tried the gun out at 100 yards from prone. This proved more challenging than firing from the bench, but nevertheless, the gun delivered five-shot groups between 1.5” and 2.5” with Black Hills 55-gr. FMJ. The most common group size encountered was 1.75”. This is similar in accuracy to the groups my AUG A2 produces, indicating that the Sabre barrel compares well to the original AUG barrel.

Setting up AUG production in a new country is a daunting task. Australia had to junk the first few thousand AUGs produced for their army due to QC and material problems with Australian Defence Industries. Thus when it came time to manufacture the gun in the U.S., Steyr was meticulous about choosing a partner and setting up production.

The final product certainly reflects this, as dealers have already bought out the entire first year’s production run.

[Acknowledgments: The author would like to thank Giles Stock, Michael Ma, and Jessie Indracusin for their assistance in producing this article.]

SOURCES:

Steyr Arms

Dept. S.W.A.T.

P.O. Box 840

Trussville, AL 35173

(205) 467-6544

www.steyrarms.com

Aimpoint Inc.

Dept. S.W.A.T.

14103 Mariah Court

Chantilly, VA 20151-2113

(703) 263-9795

www.aimpoint.com

Black Hills Ammunition

Dept. S.W.A.T.

P.O. Box 3090

Rapid City, SD 57709-3090

(605) 348-5150

www.black-hills.com

LaRue Tactical

Dept. S.W.A.T.

850 County Road 177

Leander, TX 78641

(512) 259-1585

www.laruetactical.com

Leupold & Stevens, Inc.

Dept. S.W.A.T.

14400 NW Greenbrier Parkway

Beaverton, OR 97006-5790

(503) 526-1400

www.leupold.com

Spartan Tactical

Dept. S.W.A.T.

P.O. Box 1319

Keller, TX 76244

(817) 201-8880

www.spartantactical.com