Sixty years have passed since the first Remington 870 rolled off the assembly line. In that time, an incredible 10 million have been produced. The popularity is well deserved, due to its durability, ease of operation, smoothness, and in no small part because it’s relatively inexpensive.

It has accompanied hunters in small aluminum flat-bottom boats, police officers in their cruisers, and military personnel on patrol. Of all the 870 versions, I particularly love the old Wingmasters—not just because of their chromed bolts, aluminum trigger guards, blued finish and walnut stocks, but also because of that insanely smooth action.

In recent years, many law enforcement agencies have scaled back the use of the shotgun in favor of a rifle caliber carbine. With budget constraints hitting many local agencies, there have been quite a few 870s sold to individual officers, and better yet, to FFLs to be sold to the public. Shotguns that were gathering dust have now been able to see the light of day.

Table of Contents

WELL-USED WINGMASTER

I’d considered having an 870 built to suit me, but never got around to it. I finally stopped procrastinating and set out to find an old beat-to-hell department trade-in Wingmaster. I didn’t care about the external condition, only that the internals were in good shape—for example, something carried in a cruiser daily but fired little.

I was in luck when I walked into GT Distributors in Dallas, Texas and noticed a rack full of LE trade-in 870s. Some were newer 870 Police Magnums, while others were the desired Wingmasters.

I purchased a fairly beat-up Wingmaster that had a “cruiser-ized” blued finish, scarred-up wooden furniture, and rifle sights. I took the shotgun home and disassembled it completely. It was evident that this shotgun, which on the outside looked like it had spent a lot of time in the rack of a cruiser, hadn’t had much in the way of range time—probably well under 250 rounds had been fired through the gun.

Modified XS Sights front with Trijicon tritium is heavily protected and offers excellent visibility day or night.

VANG COMP SYSTEMS

There are several names in the shotgun building and refurbishing business, but the one that kept coming up most often was Hans Vang, owner/operator of Vang Comp Systems (VCS). Multiple law enforcement agencies at federal, state, and local levels trust Hans and company to provide them with the best shotguns on the market. It says something that VCS is the only Remington authorized warranty repair shop outside of the factory.

It’s not just the work that VCS provides that makes them stand out. The parts they design and build are made for a lifetime of heavy use. These include parts like Vang Comp’s Detachable Side Ammo Carrier (DSAC)—which allows extra shells to be attached to the shotgun without fear of over-torquing the receiver—stainless steel magazine followers, +1 and +2 magazine extensions, and front and rear sights built like a locomotive.

I contacted VCS expecting to speak to the assistant to the assistant, but was pleasantly surprised when I was transferred to the man himself. In the conversation that followed, I could tell that this shop is very customer service oriented.

Fully adjustable Vang Comp rear peep sight is built like an EMD locomotive and offers four inches of M1913 rail.

HOW CUSTOM?

I still couldn’t decide if I wanted to stay on the affordable side of things or go “full house” on the shotgun. Truth be told, I’ve always wanted a full-on custom shotgun. That said, I know the custom shotgun isn’t in every reader’s budget. I ended up doing both.

Unfortunately, there were no more reasonably priced PD trade-in 870s in Dallas. Trust me, I looked. In stepped friend and fellow S.W.A.T. Magazine writer Ed Lawrence with his 870 Wingmaster in riot configuration from 30 years ago.

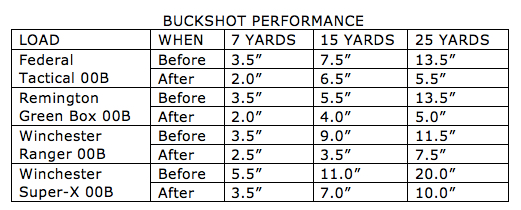

“BEFORE” TESTING

Before I sent these shotguns to VCS, Ed and I met at a local indoor range. We selected four different 00 buckshot loads to test the before and after patterns. We chose distances of seven, 15, and 25 yards, with the thought that these run the gamut of distances a shotgun loaded with buckshot will be asked to cover for the armed citizen or cop on patrol.

At seven yards, keeping all the buckshot on an FBI QIT silhouette target was easy. But once we hit 15 yards, things began to change, with pellets sometimes missing the silhouette. At 25 yards, we saw even fewer pellets inside the target’s outline.

Herein lies one of the biggest knocks against shotguns. Every time you pull the trigger, you’re sending eight, nine or more pellets downrange. You are accountable for every one of them, and that old legal expression, “There’s a lawyer attached to every bullet” is multiplied with a shotgun loaded with buckshot.

XS Sights Big Dot bead sight with Trijicon tritium is an excellent choice for those looking for a replacement for bead sights.

START THE REFURBISHING!

Both shotguns were going to be completely refurbished and rebuilt with new parts. The first thing done to both shotguns was installing the new Flex-Tab system. Included in the Flex-Tab system are new action bars, a new bolt sled, new right/left shell stops, and most noticeably a new lifter with a cutout in it. This system makes a malfunction, however unlikely, far easier to clear.

Staying inside the receiver, the next modification performed was to drill out the old ejector and replace it with a new one. The new ejector was restaked and excess material ground down. The excess material was smoothed down so you can barely tell any work was done. A little extra attention to detail certainly goes a long way. The new ejector allows me to fire three-inch Magnums should I feel the need to punish myself.

Both shotguns had new VCS steel two-round magazine extension tubes added. These magazine extensions are machined out of solid bar stock and make having a mag tube-to-barrel clamp obsolete. I like that it has a front sling plate that fits one-inch-wide slings, but that it’s also reversible for left- or right-handed shooters.

Also added was a VCS stainless steel magazine follower. It’s an ingeniously designed part that replaces those neon plastic ones. On the outside of the follower are ridges that reduce the bearing surface. This allows the follower to slide more easily within the tube, and it cleans the tube as well. When cleaning the shotgun, simply remove the magazine extension tube, spring and follower. Any dirt and grime will be on the follower. Since the interior of the follower is hollow, in a low- or no-light situation, your fingers will be able to instantly tell you if the tube is empty.

Stainless steel VCS follower offers fast visual and tactile reference.

SAFETY AND STOCK

Something often overlooked on shotguns is the safety. VCS designed their Big Dome safety to be easy to acquire with both bare and gloved hands. Both shotguns had this safety installed. It makes an audible click that lets you know whether it’s engaged or disengaged. This may be a bit controversial to some, but to be honest, it really doesn’t bother me. When the safety is off, it protrudes enough that the thumb of a right-handed shooter can re-engage the safety.

Ed’s shotgun already had a customized stock. Mine still had a nasty looking 14-inch length of pull walnut stock with a 1½-inch recoil pad. While entirely usable, I wanted something a bit more functional. What I got was a stock with a 13-inch length of pull. It’s made by Hogue and incorporates a pebble-textured area in the pistol grip as well as on the forend. The rubber is not overly tacky but provides a sure grip. The rest of the stock is of a hard synthetic. A very generous recoil pad provides a good non-slip surface on the shoulder.

I opted to have the DSAC installed on my shotgun. This design alleviates the problem with some ammo carriers, whose designs allow the screws to be over-tightened, causing the action to bind.

One thing that makes this ammo carrier so slick is its hook-and-loop material, which allows you to pull an empty ammo carrier off and add a fresh loaded shell carrier in seconds.

Vang Comp’s Detachable Side Ammo Carrier lets shooter keep ammunition and change ammunition type quickly.

SIGHTS

Sights are of huge importance. There are a few different styles, each with their own pluses and minuses. The most common are bead, rifle and ghost ring, but more and more red dot sights are making their way onto the old scattergun. When it comes down to it, it truly is up to the end user of the weapon and how they intend to use it.

I decided to have VCS ghost-ring sights installed. The rear is a ghost ring protected by two robust wings. The receiver is drilled and tapped, and the rear sight is also silver soldered on to provide maximum durability.

Different from other rear ghost-ring sights is that there is also a four-inch piece of M1913 Picatinny Rail. This gives the shooter the option of adding a small red dot sight like an Aimpoint T-1, Trijicon RMR, Insight Technologies MRDS or Leupold Delta Point in addition to the iron sights. We all know the benefits of having a red dot on a carbine, and the benefits on a shotgun should be apparent as well.

The front sight is of a similar robust design. The base of the sight is of heavy-duty construction. The post is an XS Sights Standard Dot with tritium lamp also protected by two large wings. Like the rear sight, the front is silver soldered in place.

Ed likes his bead sights and was hesitant to change because he intends to use his shotgun with buck only, and bead sights are perfect for that. That doesn’t mean bead-sighted shotguns can’t accurately deliver slugs—they sure can—but in my experience, a little extra practice is necessary. I convinced Ed to get an XS Big Dot bead sight with tritium dot installed on his shotgun.

Machined from solid bar stock steel, Vang Comp’s magazine extensions set the industry standard for strength and durability.

BARRELS

Besides all these features, the folks at VCS are known far and wide for the magic they perform on shotgun barrels. Remington, Mossberg, and Winchester shotguns, semi-autos and pumps are all able to take advantage of the VCS process.

Typical shotgun barrels have a rather abrupt bore and forcing cone. This leads to pellets deforming, which is a main reason for “flyers,” or pellets that stray from the group. This has given shotguns the reputation of being a bit of an imprecise weapon. The gas created from the shell firing also hits this shortened area, which helps give the 12 gauge its notorious recoil.

The Vang Comp System is a process in which the barrel is back bored and the forcing cone lengthened. This gives the pellets an easier path and reduces their deformation. Also the gradual forcing cone allows for more of the gas to go farther down the barrel, thus reducing recoil. Ports at the 10 and 2 o’clock positions can be optioned, which further reduces recoil and muzzle climb, and finally the ports reduce the amount of muzzle flash.

Ed Lawrence’s 1980s vintage 870 Wingmaster Riot after refurbishment by VCS.

“AFTER” TESTING

I can tell you about all the features of these rebuilds, but it’s the performance that dictates whether the money spent was worth it.

In initial firing at the range, we noted that while Ed’s shotgun ran very well, mine didn’t. We experienced several non-shooter-induced failures to feed, as well as several failures to extract that almost required the mortar technique to clear. It didn’t matter if I used high or low brass hulls, nor did it matter if it were buckshot or slugs. I tried several things, but nothing solved the problem. A call to VCS and it was taken care of. It turns out I had a faulty magazine spring. Once replaced, my shotgun ran like a freight train.

With the same buckshot loads, it wasn’t a problem keeping the pellets on the paper, nor was it an issue keeping the pellets in the silhouette—it was where in the silhouette we wanted to put them. It was fun. The reduced recoil made us forget we were actually shooting shotguns loaded with buckshot.

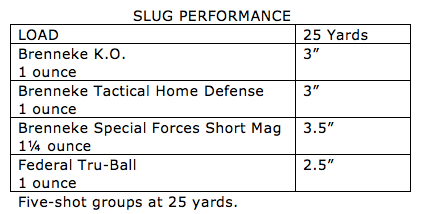

Because I wanted to use my shotgun as a feral hog slayer, I chose to also test fire four different slugs from two different manufacturers—Brenneke and Federal. My four chosen loads were Brenneke K.O., Tactical Home Defense, Special Forces Short Magnum, and Federal Tru-Ball slug. The K.O. is what some would call an old standby, while the other three are relative newcomers to the market.

The area of Texas I would be hunting rarely gives a shooter distances of over 50 yards, but due to limitations on where I could shoot slugs on local ranges, I wound up sighting in at 25 yards, which might put me an inch or two low at 50. Additional sighting would follow once I got out into the country before hunting.

Author’s 870 Wingmaster after complete rebuild by pros at Vang Comp Systems.

FINAL VERDICT

There’s a classic feel to handling a 30-year old 870 with wood stocks and bead sight, but a lot has changed in the last few decades. While a bead-sighted shotgun may be adequate for typical close-range work, as soon as the ranges stretch, this can become an issue. Though the strength of a shotgun loaded with buckshot is multiple hits, only hits count, and misses are a liability.

When it comes to using slugs, you really need better sights to milk the usability out of them at greater distances. There have also been enhancements in function and reliability of parts and accessories, as represented by the improvements VCS installed in our test shotguns.

While the Remington 870 has been—and remains—a good shotgun, Vang Comp Systems makes it great.

SOURCES:

Vang Comp Systems

(928) 636-8455

www.vangcomp.com

Brenneke USA

(800) 753-9733

www.brennekeusa.com

Federal Cartridge Company

(800) 831-0850

www.federalpremium.com

GT Distributors – Dallas, TX

(972) 279-1592

www.gtdist.com

XS Sight Systems Inc

(888) 744-4880

www.xssights.com