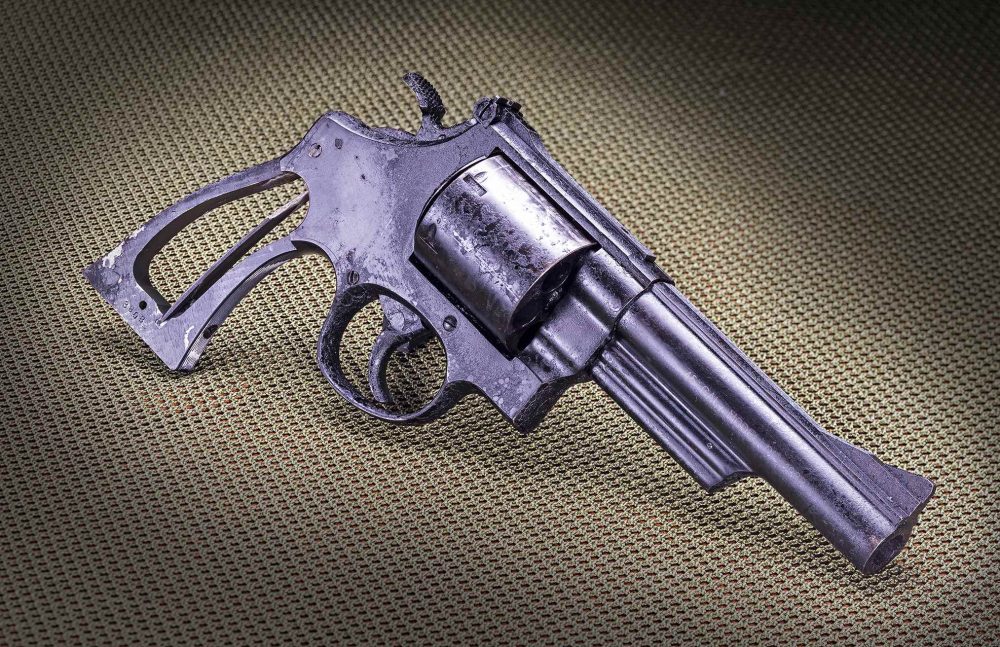

Author’s Smith & Wesson Model 15 before being restored as a cutaway. Photo: ROBAR

After my house was destroyed by a fire on 10 April 2005, Kevin McClung of Mad Dog Knives helped me clean up my firearms so I could read the serial numbers and report them as lost to the BATF. Firemen had unceremoniously dumped them all into a pile in my backyard. Kevin and I put them in a 55-gallon barrel to take them to his shop so we could run a cutting torch through the receivers.

About a week later, Kevin called to say he believed several of the firearms were salvageable.

Making custom knives for a living, Kevin understands how to heat treat metal and, under his expert guidance, we were able to restore several of my firearms (PROJECT PHOENIX: Weapons Rise From the Ashes, December 2005 S.W.A.T.). My favorite revolver—a limited-edition Smith & Wesson Model 25 chambered in .45 Colt—was not among them.

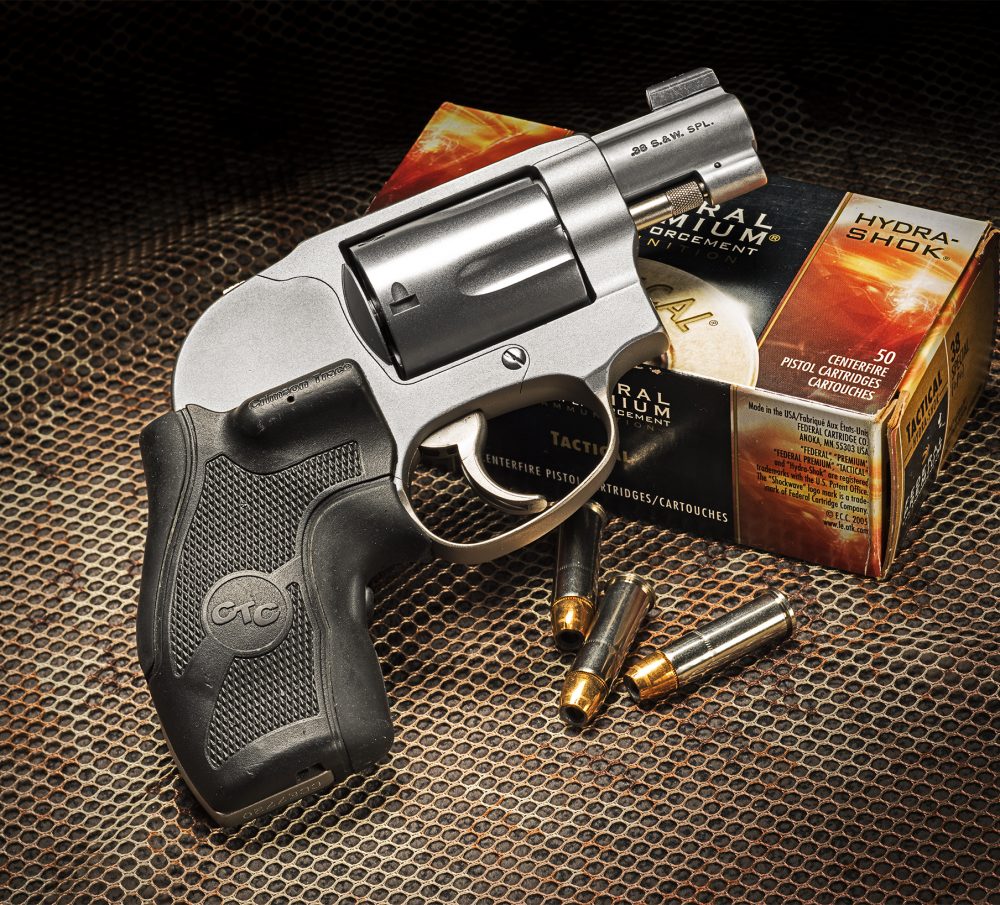

Completed cutaway Model 25. Except for actually firing, revolver is fully functional in all regards. Photo: ROBAR

Table of Contents

S&W MODEL 25

Although a limited edition, I had bought it to be more of a shooter than a collector’s piece. I sent it to a gunsmith who came highly recommended and had resigned from the Maricopa County Sheriff’s Office (AZ) due to the demand for his services.

He narrowed and smoothed the trigger for optimal double-action (DA) work and performed the best trigger job I’ve ever seen. It ended up having a seven-pound DA pull and a single-action let-off of just 2.5 pounds—with reliable ignition! In short, this was one sweet-shooting wheelgun.

After the fire, I simply could not bring myself to run a cutting torch through the frame and cylinder before junking it. For the next 11 years, it languished in a bucket of oil to protect it from completely rusting away.

One of Hansen’s Kimber 1911s that was “lost” in the fire.

ENTER ROBAR

Several months ago, I called Freddie Blish, owner of ROBAR, and asked if he thought the revolver could be restored. With no promises made, Freddie told me to send it to him to see if it were possible.

A couple of weeks later, Freddie advised me that he had talked to some of the industry’s top gunsmiths and metallurgists and also to Smith & Wesson, The final determination was that while the barrel was likely OK, the cylinder might have lost enough temper to make it unsafe for modern ammunition. His suggestion was to turn it into a wall hanger.

Since I won’t be around forever, I dreaded the thought that years from now a family member would load it and have it blow up in their face. I asked Freddie to run a torch it and dispose of it. Sad day, but I actually expected the news.

But the next day, Freddie came back to me and asked if I would like to have the gun turned into a working “cutaway” for instructional as well as novelty purposes. Great idea!

I have a long relationship with ROBAR, both with their coating technologies and the firearms made by them, and their quality has always been top notch. When I got the revolver back in mid-September, my feelings about ROBAR were reinforced—in spades.

Same Kimber after cleaning, re-heat treating, and new parts. Pistol now has more than 5,000 rounds through it.

NP3—ACCEPT NO SUBSTITUTES

With the exception of the rear sight, the entire revolver, both internally and externally, was finished in NP3®. Developed by Robbie Barrkman about 30 years ago, NP3 combines nickel and PTFE (Teflon®) at the molecular level, resulting in a finish that is not only extremely corrosion resistant, but also provides high lubricity. The color is an attractive satin gray. My experience with NP3 is that the more a firearm’s action is worked, the slicker it gets. Usually the only cleaning required is to wipe the gun off with a dry cloth.

Often copied and marketed under various monikers, only NP3 is the real McCoy. Caveat emptor.

As a side note, the finish is not restricted to guns, and is even used in the aerospace industry. If it’s good enough for the space shuttle, it’s good enough for my firearms.

The revolver now wears a set of beautiful smooth Super Target Walnut stocks (grips) made by Altamont Company.

Before his untimely passing, Pat Rogers sent his well-worn S&W M38 to Robar for refinishing. Photo: ROBAR

THE PHOENIX

The Model 25 “Phoenix” operates like any other revolver both in single- and double-action modes, as do the cylinder release and the locking parts on the ejector rod. The only difference, since the revolver is unsafe to fire, is that Robar neutered the firing pin, ensuring no live round can be ignited. I used my Lyman Electronic trigger gauge, and the Model 25 still had those sweet seven-pound D/A and 2.5-pound SA pulls.

As mentioned, I was able to restore several firearms: an AR-15, two Kimber 1911s, a Ruger Bearcat, and a few others. All the steel firearms were carefully re-heat-treated. Each was also placed on a device to confirm they were of the proper Rockwell hardness. The AR-15 was cleaned and then re-anodized. Small parts and springs were replaced as needed.

If not for Kevin’s suggestion that we try to salvage anything from the ashes, I would never even have considered it. This is not an undertaking for the casual hobbyist, but for someone who specializes in this type of restoration. But a firearm not capable of being fully restored does not mean it is time for the scrap metal pile.

Pat’s finished M38 was refinished with NP3. Robar also machined off the original front sight, milled a dovetail in the barrel, and installed an XS/24-7 standard dot front sight. Photo: ROBAR

SHOW, NOT TELL

While an interesting conversation piece, I was recently able to put the M25 back to work. I taught a concealed carry class just a few weeks after I got the Phoenix back from ROBAR. It was an eclectic group of a dozen students, but what made the class unique was that every student had brought a revolver—quite a difference from the polymer striker-fired compacts prevalent in most classes.

Using the M25 as a visual aid, I could show students exactly how their firearm worked, rather than try to explain it. It was such a great experience for them—as well as for myself—that I’m considering turning a Glock and one of my less-expensive 1911s into cutaways for future classes.

If you’re thinking about refinishing a gun for either cosmetic or functional reasons, check out ROBAR. Besides NP3, they have other finishes that I have used and rely on. I highly recommend their work.

SOURCES

THE ROBAR COMPANIES, INC.

(623) 581-2648

www.robarguns.com

ALTAMONT COMPANY

(800) 626-5774

www.altamontco.com