In the beginning, there was Bullseye pistol shooting, and it was good. Then came High Power Rifle shooting, and that too was good. And then PPC (also known throughout the land as Position Bullseye shooting), and Handgun Silhouette, and Combat (now Practical) Pistol, and the same for Rifle, and 3 Gun, and they were all good. And many, many, many rounds were fired. And on the day of the match, the ammo bunker was empty, and this was not good!

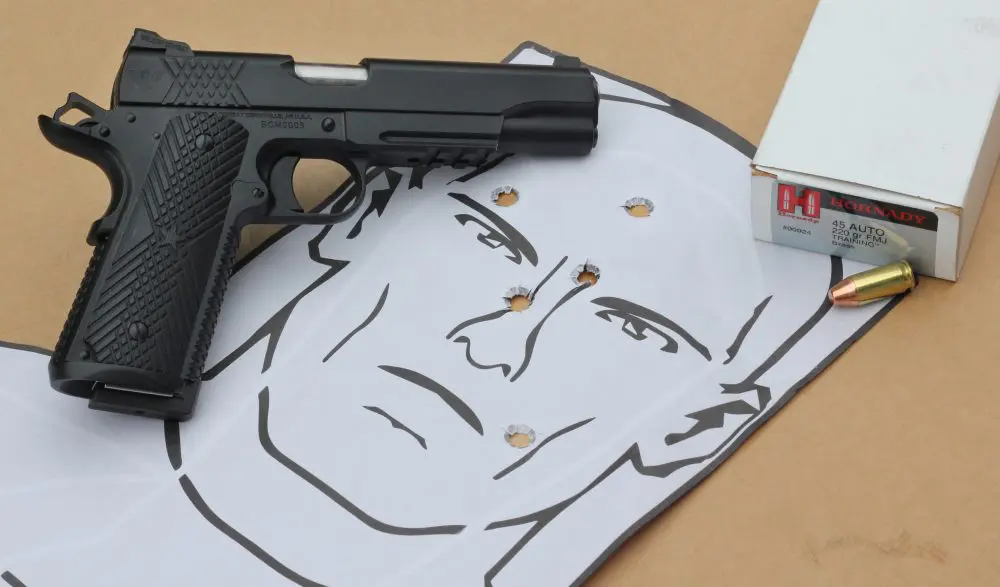

You have worked hard all week, putting in some overtime to insure your weekend will be free for the big match. Your pistol has been cleaned and freshly lubed, all your gear is in your bag, all you need to do is grab some ammo and load the car. Then you reach for your match ammo, only to experience that sinking feeling—you have shot it all up! You search, becoming increasingly desperate, finding a few rounds here and there, but not enough for the match.

I have been there, done that—and more than once.

RELOADING WAY BACK WHEN

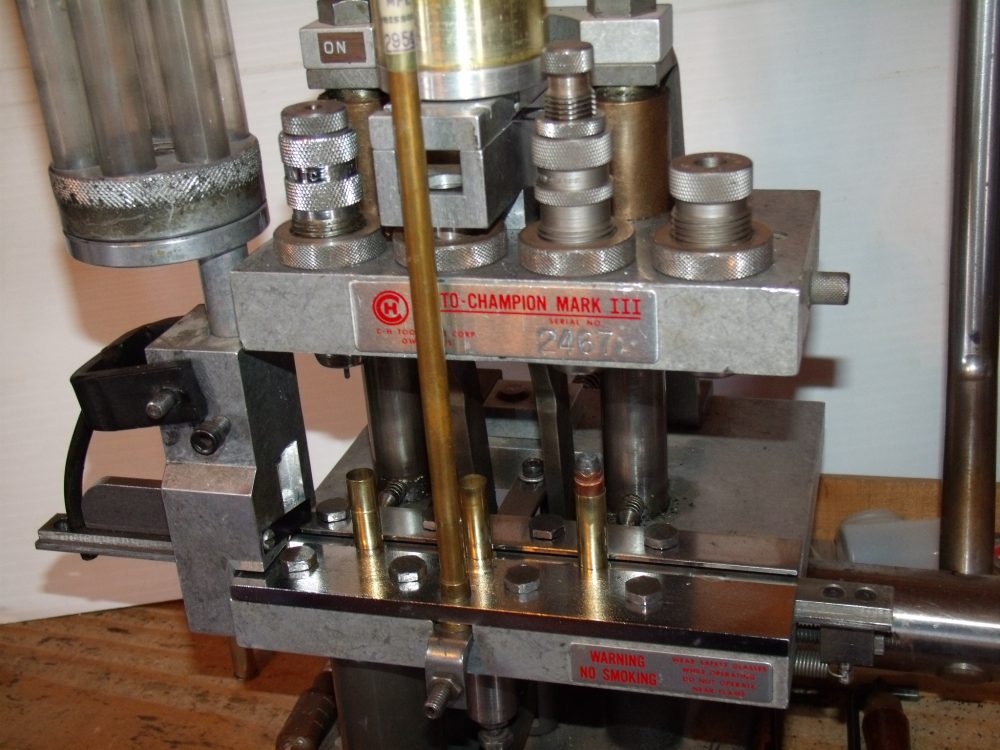

Back in the day, there were only two progressive reloading presses—the Star Machine (made by the Star Machine Company) and the C&H Auto-Champ. Both were expensive, rare, and only capable of loading pistol ammo. The only other presses readily available were the solid single-stage presses.

On a single-stage press, you screw in a die, perform that operation on some cases, then unscrew the die and screw in the next die. If you need more than one box, it can turn into a marathon.

After the third (or was it the fifth) time I experienced that sinking feeling of another late night before a match loading ammo, it was time to find a better way. At the time I was shooting Bullseye pistol, High Power Rifle, and PPC, as well as the early Combat (now the more politically correct Practical Pistol) matches. It was going to be tough to figure out a way to keep all those ammo supplies at a minimum level.

After thinking on it awhile, I came up with a system to eliminate that late-night loading session (which was certainly not helping my scores) by changing the way I did things. This was very early in my law enforcement career, and time and money were both in limited supply.

Batches of brass, the RCBS Rockchucker, and four pounds of Bullseye—life is good.

THE SYSTEM

Unlike today, however, components were easy to find. So step one was to lay in a goodly supply of components in the calibers needed, particularly large quantities of matching brass, so I would not have to sort cases. My existing mixed cases were relegated to practice ammo.

It also required that I settle on one powder charge for pistol ammo. While the system does lend itself to experimentation, finding one formula was the best way to make it efficient. That was no problem, as back then Bullseye was the powder of choice. Later it became WW231, and then, as choices expanded, other powders. I bought bullets by the thousands, primers the same way, and powder in four- or eight-pound kegs.

Step two required obtaining suitable containers to hold the brass in its various stages. At the time, the easy and cheap solution was coffee cans—durable, large enough, and best yet, free! Each can was labeled with the caliber and what stage the brass was at. Can 1 was .45, dirty brass. Can 2 was .45, clean brass. Can 3 was .45, sized and deprimed brass, and so on.

With auto case feed, straight line C&H Auto Champ is still cranking out quality loads like this .38 Special over 40 years later.

The system works like this: each evening (or whenever time permits), perform one operation on the brass, for example size and deprime all the clean brass. Cleaning went on while I was doing other things (we used rock tumblers in those days). So some evenings, all I did was size and deprime all the clean brass. The only combined operation was dropping powder charges and seating bullets.

Whenever you have spare time, look to see which can is empty and do the operation needed to fill it. Once you develop a rhythm and have some experience, you can do any operation except dropping powder charges with the TV on! When the powder can is open, the TV and all other distractions must be off.

The critical point was making sure that the can of sized, deprimed, case-mouth belled, primed (i.e., “ready”) brass was never empty. That way, if you once again shoot up your match ammo, all you have to do is drop powder charges and seat bullets—an hour or so is all you need to have match-ready ammo!

It’s late, and that’s not enough ammo to get through Stage 1. This is not good!

Once my finances allowed it, I bought a progressive press—the Auto Champ. Today, more than 40 years later, it is still in use to load my .45 and .38 Special reloads. It stands next to my Dillon 550b, where the 9mm, 5.56, 7.62 NATO, and .30-06 get reloaded. The other calibers used in limited amounts, such as .44 Special and .44 Magnum, .45-70, and .303 British are still loaded on the old RCBS single-stage press. In these calibers, a batch may be only 20 or 50 rounds. And I have enough time that all I do is load some when I feel like it, since I retired and long ago settled on standardized loads.

Perhaps I should call this “flow through” reloading, but I settled on “batch” reloading, because I still have batches of uniform brass that get processed in this manner.

Now I have the time—all I need are the components.