A bullet not fully crimped can creep forward and lock up a revolver.

In reloading, a number of factors bear on the accuracy and safety of your ammo. As you reuse your cases, they wear and stretch. At some point they will fail. All things that get used will, and cases are subject to various stresses that ultimately result in failure.

One question we all have is, “How many times can I reload a case?” The answer is a lawyerly, “It depends.” It depends on the age of the brass, the pressure of the load, whether it’s a pistol or rifle round, and how accurate you need to be.

Few among us shoot at a level where the accuracy of the rifle, pistol or ammo is a factor. To find out, simply compare how you shoot with some factory ammo with a reputation for accuracy, with how you shoot with your reloads. If there is a meaningful positive difference between the factory stuff and your reloads, it’s time to sharpen your reloading skills. If not, your reloads are not a factor.

Many national and international titles in all kinds of shooting sports have been won with hand-loaded ammo.

Catastrophic .45 ACP case failure.

Table of Contents

EPIC FAILS

The primary cause of case failure is pressure. If you are loading toward the high end of the pressure spectrum for your caliber and bullet weight, you are subjecting your cases to high pressures and shortening their life. I have always felt that if I need to get above the mid-range loads for a particular bullet weight in a particular caliber, then it’s time to buy a bigger gun (as if I need a reason to buy another gun!).

High-pressure loads don’t do any favors for your firearms either, as they tend to accelerate wear.

The next reason for case failure, and one we can control, is how your reloading dies are set. If you are sizing your cases to the smallest possible dimensions, you are working the brass more than may be necessary. However, if you reload for more than one gun in that caliber, this may be necessary.

The same is true if you crimp your bullets too tight, especially if you bell the case more than needed for bullet seating. This spreading and crimping of the case mouth works the brass and leads to case mouth cracks.

Could this be too much pressure?

Ultimately, all cases have a service life. Some fail with minor cracks, while some become catastrophic failures, occasionally damaging the gun (and sometimes the shooter). Other failure types just bring your shooting to a screeching halt.

In revolvers, case failures usually start with neck cracks. Unless you are at the very highest levels of competition, a minor case neck crack (1/8 inch or less) can be ignored one time.

There may be a slight drop in velocity, but it will be tiny. The one situation where attention must be paid is if the crimp will not hold the bullet. If the bullet creeps forward, it can lock up your revolver and you are done until you drive that bullet back into the case. In lightweight revolvers with heavy loads, I have seen this happen with some lots of factory ammo, usually of foreign make.

If you are shooting in a semi-auto pistol or any kind of rifle, a more dangerous situation can arise. The bullet may be pushed back into the case during feeding, unseen by the shooter. Fire the round, and the pressure will spike, perhaps damaging the gun and the shooter.

Catastrophic case failures in revolvers sometimes go unnoticed until you extract the empties. In semi-auto pistols, they can be more exciting. I have had any number of cases crack over most of their length and not noticed it until I picked up the brass.

Look for bright lines to cull worn-out rifle cases.

MY PERSONAL FAILURES

On rare occasions, I have had the base of a case blow out. Believe me, you will know if this happens! In a chamber that is not fully supported, the gasses blow down into the magazine, sometimes blowing off the base of the magazine and scattering the ammo, spring, and follower all over the range.

If you have wood grips on your pistol, they often split and have to be written off. Other materials usually contain the gases, limiting damage to the magazine. The shooter mostly has very minor injuries: a stinging sensation in the palm that goes away in a few moments, and perhaps a wood splinter or two.

Over the years, I have had one case head break off in a .45, leaving the tube in the chamber until I removed it with a cleaning brush. In rifles, I have had several case head separations, where the tube has to be removed using a cleaning brush inserted into the chamber.

I have had two or three cases blow out into the magazine well. Considering I load and shoot at least 10,000 rounds a year and have been doing so for close to 50 years, these are rare events.

I generally shoot my pistol brass until it cracks or I lose it. I find moderate loads in 9mm and .45 allow long service life. I have some .45 brass that has been fired so many times the headstamps are illegible. I save those cases for practice.

Sample split pistol cases.

CASE INSPECTOR

There is an easy way to pick out cracked pistol cases in a pile of brass—put them into a bag and shake them! I use a mesh bag, which lets the range dirt fall out during the process. Even with my seriously degraded hearing, I can hear the musical tone of a cracked case in the bag. Then I sort the cases until I locate the broken one. At the same time, I look at the cases for bright lines, which suggest case head separations—more on that under rifle cases.

I recheck for cracked cases every time I handle them. If one slips through and I spot it only after it is loaded, it’s time for a “reloader’s eraser”—a bullet puller.

Rifles are a much more serious matter, for two reasons: The pressures are much higher, and your face is much closer to the scene of the action. Cases reloaded for rifles need to be individually and closely inspected. As you know, bottleneck rifle cases “grow” with use, as the pressure tends to push the brass toward the neck. Ignore this situation at your peril! A steel hand grenade going off just inches from your face is not a good thing.

Case head separation on left, bright ring on case on right.

WHY WE MUST CHECK

I know of one shooter who hand loaded some ammo for a rare collectible rifle. He fired two rounds and had to hammer the bolt open each time. In police work, we call this a clue. He ignored the evidence, and the third shot blew the extractor into his forehead, instantly killing him.

Pay attention! You must trim your brass, for if the brass flows into the chamber neck, pressures skyrocket.

On rifle cases, check for case neck cracks and bright rings close to the case head. If trimming the brass back to size eliminates the crack, you can use the case again. If the crack extends below the trim line, discard the case.

The bright rings are a warning of incipient case head separation. If you transport your ammo in plastic boxes, check to see if the ring is caused by the case rubbing against the box. I nearly threw away some match brass until I noticed the source of the shiny rings was my plastic ammo boxes.

But an uneven ring that does not extend all around the case can be a sign that the case head is about to separate. Discard all those cases.

These cases are battered but still usable for practice.

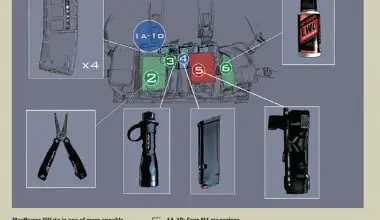

When I discover a cracked case on the range, I use my multi-tool to crush the case neck. There is no way I want that case creeping into my ready-to-load brass.

Rather than just throwing away all my cracked brass, I toss it into my “brass box” along with all my non-reloadable brass and expended primers. About once a year, I sell the brass and take my wife to dinner on the proceeds. This tends to soften the blow from buying more powder, primers and bullets!

Reloading is like driving a car—completely safe as long as you know and follow the rules. Break the rules and there will be a price to pay.

Seth Nadel retired after serving 27 years as a Senior Special Agent with U.S. Customs. He was a firearms instructor for 25 years, including nine years as the lead firearms instructor at the Tucson Customs Academy. He is also an NRA Certified Metallic Reloading Instructor.