Sunglasses are an essential item of personal protective equipment. Selecting the right sunglasses is essential. They not only need to protect your eyes from the sun but from unexpected eye hazards as well. Wearing the proper eyewear could prevent more than 90% of all eye injuries.

Non-prescription sunglasses sold in the U.S. are regulated by the Food and Drug Administration (FDA) as class 1 medical devices and are required to conform to basic safety standards. Compliance with the voluntary American National Standards Institute (ANSI) Z80.3 standard is considered acceptable. ANSI Z80.3 includes standards for impact resistance, flammability, biocompatibility, and optical properties.

Table of Contents

PROTECTION

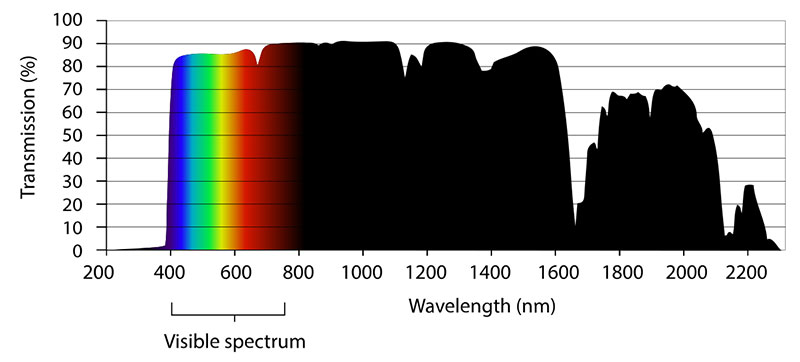

Ultraviolet (UV) protection is covered by the ANSI Z80.3 standard, which also includes elements such as light transmittance, including being able to distinguish between green and yellow light in average daylight.

UV is invisible to the human eye. Long-term exposure to UV has been linked to serious eye damage. The three types of UV radiation are UVA, UVB, and UVC. UVA is the most damaging to the eyes, although UVB has also been linked to eye damage. Most UVC is filtered out by the ozone layer.

High-energy visible (HEV) radiation or blue light can also damage eyes. Although HEV rays have longer wavelengths and lower energy than UV rays, they penetrate deeply into the eye and can cause retinal damage. While some sunglasses block HEV, the FDA doesn‘t require it.

FDA safety standards for sunglasses don’t provide the level of impact protection that’s essential for active sports or duty/tactical applications. Most lenses shatter into fragments when hit by objects moving at easily reached speeds, according to ophthalmologist Dr. Paul F. Vinger, an Associate Clinical Professor at Tufts Medical School in Medford, Massachusetts. Dr. Vinger conducted 350 impact tests on various types of glasses.

In the study, tennis balls propelled at 40 mph shattered high-index plastic lenses, while balls at 55 mph shattered allyl resin (also known as hard resin or CR-39) plastic lenses and those at 89 mph shattered glass lenses. Polycarbonate lenses didn’t shatter at 89 mph.

Polycarbonate lenses with a center thickness of 1 millimeter withstood the impact of a baseball fired at 94 mph. Lenses made from glass, allyl resin plastic and high-index plastic shattered at that speed, according to the study.

Developed commercially in 1957, polycarbonates are extremely tough, impact-resistant thermoplastics that have many applications. They’re available in different grades and proprietary blends. Polycarbonates are known by a variety of trademarked names, including Lexan®, Makrolon®, Zelux®, Plutonite®, and others.

Polycarbonate lenses are the most impact-resistant lenses available. They’re lighter and thinner than glass or plastic lenses and have from 10 to 20 times more impact resistance. Polycarbonate lenses have excellent optical clarity, although they can’t match glass lenses in this regard. Polycarbonate inherently blocks 100% of UV and HEV up to 400nm (UV400 protection). It does scratch fairly easily and requires a scratch-resistant coating for durability.

Trivex® is a rival to polycarbonate developed in 2001. Trivex lenses and polycarbonate lenses are comparable in impact resistance, inherent UV protection, and scratching. Trivex is about 10% lighter than polycarbonate and may have a slight edge in optical clarity but costs a bit more.

The current ANSI Standard for Occupational and Educational Eye and Face Protection (ANSI Z87.1-2010) includes requirements for high mass and high velocity tests. Protective eyewear was previously classified as either basic or high impact. In Z87.1-2010, the distinction now is that they’re either non-impact or impact rated.

In the ANSI high mass test, a one-inch steel ball is dropped on the lens from a height of 50 inches. In the high velocity test, a 0.25-inch steel ball is shot at the lens at 150 fps. To pass both tests, no part of the lens may touch the eye.

ANSI Z87.1-2010 also guarantees optical precision, impact resistance on frames equipped with prescription and standard glasses (made of 2mm thick polycarbonate), anti-fog and anti-scratch coating, UVA and UVB filtering, frame resistance, and side protection.

Impact rated eyewear carry the Z87+ mark on both the lens and the frame or housing. Compliant prescription products are marked with Z87-2+.

The U.S. military standard for combat eye protection [MIL PRF-324320 (GL)] is even more stringent. MIL-PRF-32432, clause 4.4.3.3, requires that ballistic eyeglasses withstand a hit with a 0.15-caliber, 5.85-grain, T37 shaped projectile at 640 to 660 feet-per-second to the primary lens. This is over six times the kinetic energy level of ANSI Z87.1 impact tests.

VISIBLE LIGHT TRANSMISSION & OTHER FEATURES

Visible Light Transmission (VLT) is the amount of visible (non-UV) light that passes through your lenses and reaches your eye. VLT is measured in percentages. For example, a lens with a VLT of 20% admits 20% of visible light and filters out the remaining 80%.

Here are some general guidelines for VLT:

10–19%: Ideal for bright, sunny conditions.

20–40%: Good for all-purpose use.

40+%: Best for overcast and low-light conditions.

80–90+%: Virtually clear lenses for very dim and night conditions

Lens colors affect how much visible light reaches your eyes, how well you see other colors, and how well you see contrasts. Dark colors (gray/green/brown) excel in moderate to bright light conditions. The darker shades are intended to cut through glare and reduce eye strain.

Light colors (yellow/gold/amber/rose/vermillion) excel in moderate to low level light conditions. They provide excellent depth perception, improve contrast, make your surroundings appear brighter, cut through glare, and reduce eye strain in moderate-to-bright conditions.

Gray and green lenses won’t distort colors. Only gray and clear lenses provide true color perception. Gradient lenses go from a darker shade at the top to a lighter one at the bottom.

Photochromic lenses are designed to darken on exposure to specific types of light of sufficient intensity, most commonly UV radiation. The lenses return to their clear state in the absence of activating light. Darkening typically takes about a minute, while lightening takes longer.

The photochromic process takes longer in colder weather and the lenses also become darker. The reverse is true at higher temps. Most photochromic lenses won’t work when driving a car because windshield blocks most of the UV rays.

Polarized lenses are designed for bright conditions where glare is a problem. They have a built-in laminated filter that allows only vertical light rays to pass through. The polarization almost totally blocks horizontal rays, thus eliminating reflected glare.

Mirrored or flash coatings are also designed to reduce glare. They do make objects appear darker than they actually are, so lighter tints are often used to compensate for this. They don’t interfere with the visibility of LCD and LED displays.

Other coatings that may be found on better sunglasses can include a hydrophobic coating to repel water, an anti-scratch coating, and an anti-fog coating for humid conditions or high-sweat activities.

Polycarbonate prescription lenses typically run about $140 with a scratch-resistant coating. If you have a stronger prescription and require high-index lenses, bifocal/multimodal lenses, specialized coatings, or polarized or photochromic lenses, prepare to pay more.

Eyewear with interchangeable lenses can be useful where weight and space are at a premium. They allow you to tailor your eye protection to different activities and environments while taking up minimal space.

FRAMES

Frame materials that may be found on brand-name eyewear include a variety of metals, nylon, cellulose acetate, and castor-based polymer. The quality and design of the eyeglass frame are greater determinants of its durability than the material from which it’s made.

Metal continues to remain popular as a frame material and is easy to adjust. Although durability is an issue with many metal frames, some are very robust. Liquid® Eyewear’s aerospace-grade aluminum alloy frames are a notable example of the latter. They’re nearly indestructible.

Nylon frames were introduced in the 1940s. Because of brittleness issues, manufacturers switched to blended nylons. Most sports and performance eyewear frames are made of blended nylons, which are lightweight and strong but not adjustable unless they have an internal adjustable wire core.

Cellulose acetate is a plant-based plastic popular on some high-end designer sunglasses. Acetate is lightweight and allows for greater color variations. Castor-based polymer is another bio-based polymer that is seeing use for sunglass frames. It’s a relatively new polymer that uses castor oil extracted from the seeds of the castor bean. It’s light, durable and features superior flexibility that can withstand repeated bending.

Impact rating, fit, and style are important. So too is compatibility with any other personal protective equipment that may be worn in conjunction with them and with any comms.

For optimal protection, the frames should fit snugly around the face in a wraparound style to prevent unfiltered sunlight from entering the eyes, as well as to provide additional coverage for protection from debris and impact and a wider peripheral view.

The availability for the frame of foam inserts that can be installed when needed to provide the protection of a goggle can be a real plus. Some frames take it even further and are designed to be easily convertible from glasses to goggles, such as the Liquid Eyewear T-Flex™.

All name-brand ballistic eyewear manufacturers offer Rx-capable models. Rx lenses may be built into the frame or into Rx inserts that attach to the frame. The U.S. Army has adopted a cross-platform Universal Prescription Lens Carrier (UPLC) as the only lens carrier platform used by its soldiers. The Army’s Authorized Protective Eyewear List (APEL) indicates which of the approved eyewear is UPLC compatible.

Regular eyeglasses should not be worn under your protective eyewear. Doing so puts you at a safety risk.

OTHER CONSIDERATIONS

Price shouldn’t be the determining factor when purchasing protective eyewear. After all, how much are your eyes worth? Also, since needs (and faces) differ, it’s always a good idea to try before you buy.

Always purchase eyewear from a reputable authorized dealer. Recent years have seen a dramatic rise in counterfeit ballistic eyewear. Caveat emptor.

Eugene Nielsen’s background includes protective intelligence investigations and threat management, as well as red teaming security consulting. He has a BA degree from the University of California. He currently owns and operates an investigative and security consulting firm and is licensed in both California and Arizona.

SOURCES

LIQUID EYEWEAR

(928) 329-0006

www.liquideyewear.com

U.S. ARMY PEO SOLDIER APEL

www.peosoldier.army.mil/equipment/eyewear

1 comment

I ordered a Pair of liqUid eye wear a few years back i love how they fit went to tHe websight to order another pair seems like they have website issues or might be out of busIness could Use some help getting pointed In the right direction or maybe another COMPANY that makes eyewear siMilar any help would be greatly appReciated